A waterjet cutter is one of the most versatile and precise cutting machines available today. From metals to stone, glass, composites, and carbon fiber, it allows workshops to produce highly accurate parts without heat damage. Choosing the right machine depends on your workshop’s size, production goals, and safety requirements.

As engineers and industry specialists with decades of experience in waterjet technology, we’ll guide you through recommended models for different types of workshops.

1. Classic Ball Screw Gantry – Reliable Choice for Most Workshops

- Expert Insight: Ball screw gantry machines are highly reliable, stable, and precise.

- Advantages: High accuracy, easy maintenance, consistent performance.

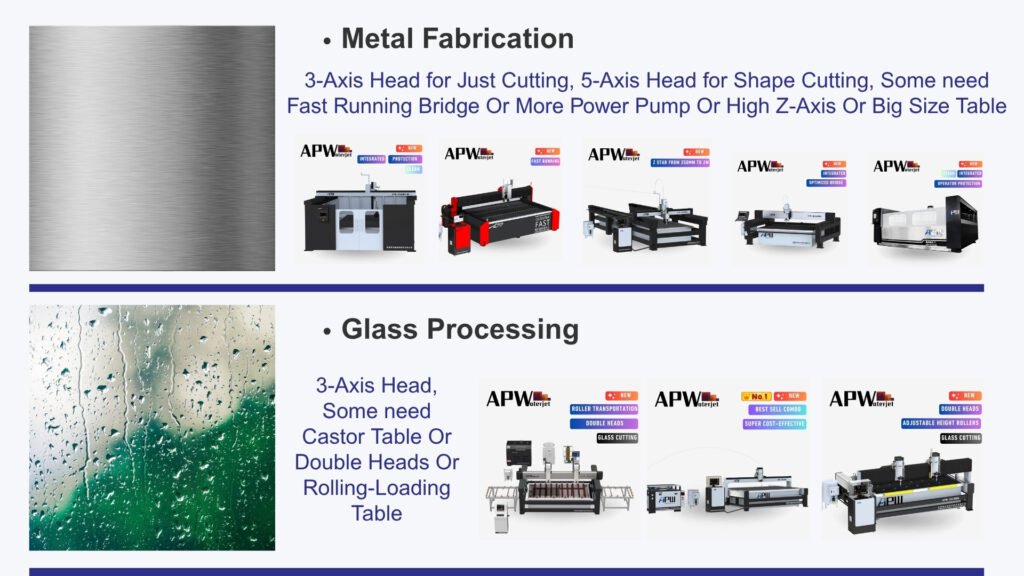

- Best For: Medium-sized workshops cutting metals, stone, or general industrial materials.

2. Fully Enclosed with Automatic Lifting Doors – Safety & Eco-Friendly

- Professional Experience: Fully enclosed machines reduce dust, noise, and risk of injury.

- Advantages: Operator safety, clean working environment, eco-compliant.

- Best For: Workshops prioritizing green manufacturing and workplace safety.

3. Gantry Type with Sliding Doors – Practical & Space-Saving

- Industry Tip: Sliding doors save floor space while maintaining safety.

- Advantages: Easy access, compact footprint, secure operation.

- Best For: Workshops with limited space but strict safety requirements.

4. Multi-Beam, Multi-Head Gantry – High Efficiency for Mass Production

- Expert Recommendation: Simultaneous cutting on multiple beams maximizes throughput.

- Advantages: Reduced lead time, consistent quality, ideal for batch production.

- Best For: Large-scale factories in automotive, aerospace, or stone processing.

5. Cantilever Type – Flexible Loading for Small Workshops

- Professional Tip: Allows 3-side loading, perfect for irregular jobs.

- Advantages: Compact, flexible, cost-effective.

- Best For: Small workshops and family-owned businesses needing adaptability.

6. Rack and Pinion Gantry – High Precision Cutting

- Industry Insight: Rack and pinion systems achieve higher positioning accuracy than ball screws.

- Advantages: Excellent for complex parts like gears, rack & pinion, electronics components.

- Best For: High-tech industries requiring precision.

7. High-Frame Gantry – Cutting 3D & Oversized Materials

- Expert Advice: Large vertical clearance enables cutting thick or tall workpieces.

- Advantages: Robust, flexible cutting range.

- Best For: Architectural, artistic, or custom 3D projects.

8. Dual Platform Tube & Plate Integrated Type – Maximum Versatility

- Industry Tip: Combines pipe and plate cutting in a single machine.

- Advantages: Cost-effective, versatile, space-saving.

- Best For: Workshops with diverse client needs or mixed-material fabrication.

9. Small Fully Enclosed Platform – Ideal for R&D & Labs

- Professional Recommendation: Compact, safe, and precise for prototyping and material testing.

- Advantages: Small footprint, enclosed for safety, high precision.

- Best For: Universities, R&D centers, and innovation labs.

10. Roller Platform Type – Continuous Glass Cutting

- Expert Insight: Roller-fed machines enable smooth, automated glass cutting lines.

- Advantages: Reduced breakage, optimized for fragile materials.

- Best For: Glass factories or workshops specializing in high-volume glass cutting.

11. Continuous 6-Axis Robotic Arm – Uninterrupted Multi-Angle Work

- Expert Insight: 6-axis robotic arms allow uninterrupted production with full flexibility.

- Advantages:

- Customizable “回” (U-shaped) cutting platform

- Operates on four sides of the workpiece

- Multiple robotic arms can collaborate

- Continuous operation without downtime

- Best For: High-end industrial workshops, automated production lines, aerospace, and complex fabrication.

Waterjet Cutter Types Comparison Table

| Machine Type | Key Advantages | Best For | Scale / Workshop Type | |

| 1 | Ball Screw Gantry | Stable, precise, easy maintenance | General industrial cutting | Medium |

| 2 | Fully Enclosed w/ Auto Doors | Safety, eco-friendly, dust & noise reduction | Green manufacturing, safety focus | Small–Medium |

| 3 | Gantry Sliding Doors | Space-saving, easy access | Limited space workshops | Small–Medium |

| 4 | Multi-Beam / Multi-Head Gantry | High throughput, batch production | Large-scale mass production | Large |

| 5 | Cantilever | Flexible 3-side loading | Irregular jobs, small workshops | Small |

| 6 | Rack & Pinion Gantry | High positioning accuracy | Precision gear, electronics, aerospace | Medium–Large |

| 7 | High-Frame Gantry | 3D / oversized cutting | Architectural, artistic projects | Medium–Large |

| 8 | Dual Platform Tube & Plate | Versatile pipe & plate cutting | Mixed-material production | Medium–Large |

| 9 | Small Fully Enclosed | Compact, safe, precise | R&D labs, prototyping | Small |

| 10 | Roller Platform | Continuous glass cutting | Glass factories | Medium–Large |

| 11 | 6-Axis Robotic Arm | Uninterrupted, 4-side, multi-arm | Automated high-end production | Large / Advanced |

How to Choose Your Waterjet Cutter

Selecting the right waterjet cutter is crucial for efficiency, cost-effectiveness, and product quality. Consider:

- Small flexible jobs: Cantilever or small enclosed platform

- Safety & eco-friendly production: Fully enclosed types

- Mass production: Multi-beam, multi-head gantry

- High precision projects: Rack & pinion or high-frame gantry

- Specialized material cutting: Tube & plate integrated, roller glass platform

- Uninterrupted, multi-angle work: 6-axis robotic arm

Choosing the appropriate machine ensures higher productivity, safer operations, and a better ROI.

About APW Waterjet

With decades of experience in waterjet cutter manufacturing, APW offers solutions for workshops of all sizes — from small R&D labs to large industrial factories.

Explore more: contacts or watching cutting videos or visit our FB or shopping in Alibaba

FAQ About Waterjet Cutter

1. What materials can a waterjet cutter cut?

A waterjet cutter can slice through metals, stone, glass, ceramics, composites, and even carbon fiber without heat damage. This makes it highly versatile for different industries.

links:

- See our recommended models for precision cutting and small workshops.

2. Can a waterjet cutter handle large or 3D materials?

Yes, high-frame gantry machines or 6-axis robotic arm waterjet cutters are designed for oversized and three-dimensional workpieces.

links:

- Check high-frame gantryadvanced waterjet

3. Which waterjet cutter is best for small workshops or labs?

- Cantilever type allows flexible 3-side loading.

- Small fully enclosed platform is perfect for R&D and labs requiring precision and safety.

links:

4. How do I improve safety and reduce environmental impact with a waterjet cutter?

Choosing a fully enclosed waterjet cutter with automatic doors reduces noise, dust, and operator risk, making it suitable for eco-conscious workshops.

links:

5. Can waterjet cutters cut both tubes and plates?

Yes, dual platform tube & plate integrated machines allow seamless switching between pipe and plate cutting, maximizing versatility.

Internal links:

- Dual platform tube advanced waterjet& plate

6. Are robotic arm waterjet cutters suitable for continuous production?

Absolutely. 6-axis robotic arm waterjet cutters support multi-arm coordination and multi-side cutting for uninterrupted production, ideal for high-end industrial applications.

links:

- 6-axis robotic armCONTACT APW