Water Jet Cutting Simples

Water jet cutting is a highly precise and versatile technology. To explore its capabilities, you can view water jet cutting samples organized by different materials such as metal, stone, glass, plastic, and composites on our official website. For a more hands-on understanding, you are welcome to contact our sales team to request detailed photos or demonstration videos of the cutting process. Additionally, you can send your own materials to our laboratory, where our experienced technicians will perform trial cuts and provide accurate data and results. This allows you to evaluate the suitability of water jet cutting for your specific materials and application needs.

Search by material

Water jet cutting is a revolutionary and highly versatile technology in manufacturing and material processing. By using high-pressure water streams, optionally combined with abrasives, it achieves precise and intricate cuts across a wide range of materials. To explore its capabilities, you can visit our official website, where a comprehensive gallery of water jet cutting samples is organized by material types, including metals like stainless steel and aluminum, stones such as marble and granite, glass of varying thicknesses, plastics, and advanced composites.

For a deeper understanding, our dedicated sales team is available to provide high-resolution photos and detailed demonstration videos, showcasing the efficiency and precision of our water jet cutting machines on different materials.

We also offer personalized trial services: you can send your own materials to our laboratory, where our experienced technicians will perform test cuts, record key data—including cutting speed, accuracy, and material integrity—and generate a detailed report. This report allows you to evaluate the suitability of water jet cutting for your specific materials and applications, enabling informed decisions and ensuring your projects achieve optimal results.

FAQ-water jet cutting samples

1. What are water jet cutting samples?

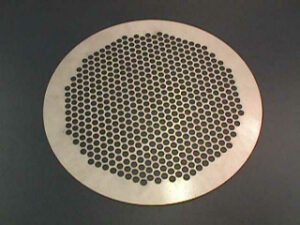

Water jet cutting samples are real examples showing the cutting results of APW water jet machines on materials such as metal, stone, glass, and composites, highlighting precision and quality.

2. How can waterjet cutting samples help in choosing a machine?

By examining water jet cutting samples, customers can compare performance, accuracy, and finish quality, helping them select the most suitable APW water jet model.

3. Are APW waterjet cutting samples available for different industries?

Yes, water jet cutting samples demonstrate applications in stone processing, metal fabrication, glass cutting, aerospace components, and more.

4. Can I request custom waterjet cutting samples?

Yes, APW can provide tailored water jet cutting samples based on specific materials and cutting requirements to meet your project needs.

5. Do waterjet cutting samples show the latest APW technology?

Yes, all water jet cutting samples reflect the latest APW water jet technology and demonstrate real-world cutting performance for industrial applications.

6. What is 3D water jet cutting and how is it demonstrated in your cutting samples?

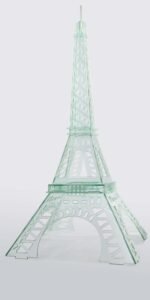

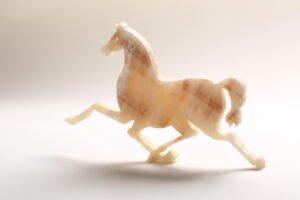

3D water jet cutting allows complex contours and angled cuts that are difficult to achieve with conventional 2D methods. Our water jet cutting samples include examples of 3D cutting on metal, stone, and composite materials, showcasing the precision and versatility of this advanced technique.

7. How does a 5-axis cutting head improve water jet cutting performance?

A 5-axis cutting head provides multi-directional movement, enabling angled and intricate cuts with high accuracy. Our water jet cutting samples highlight the advantages of 5-axis technology, showing smooth curves, bevels, and complex geometries that standard machines cannot achieve.

8. What materials can be cut with pure water (HP pure water) jets?

Pure water jets, without abrasives, are ideal for soft or delicate materials such as foam, rubber, food, and thin metals. Our water jet cutting samples demonstrate how pure water cutting achieves clean edges without thermal or mechanical damage, preserving material integrity.

9. When should abrasive water jet cutting be used?

Abrasive water jet cutting is used for harder materials like stainless steel, granite, glass, and composites. The addition of garnet or other abrasives enhances cutting power. Our water jet cutting samples illustrate how abrasive water jets achieve precise and efficient cuts on tough industrial materials.

10. How can I request custom water jet cutting samples for my project?

You can send your own materials to APW, and our technicians will perform trial cuts using either pure water or abrasive water jets, including 3D or 5-axis cutting as needed. Detailed results and water jet cutting samples will be provided to help you assess suitability and precision.

watch water jet cutting videos

Water jet cutting samples are shown on the APW Youtube Channel