Water Jet Application Case

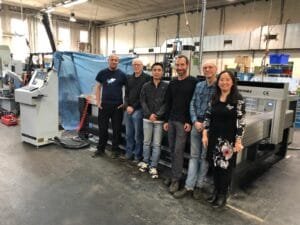

Water Jet Application Case Studies: Your Roadmap to Success

Learn from real water jet application case studies, exchange experiences with peers worldwide, and gain insights from water jet cutting experts. These practical examples help accelerate your business growth, improve operational efficiency, and maximize your commercial profits.

Glass Cutting

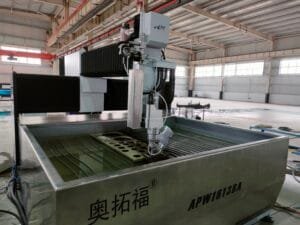

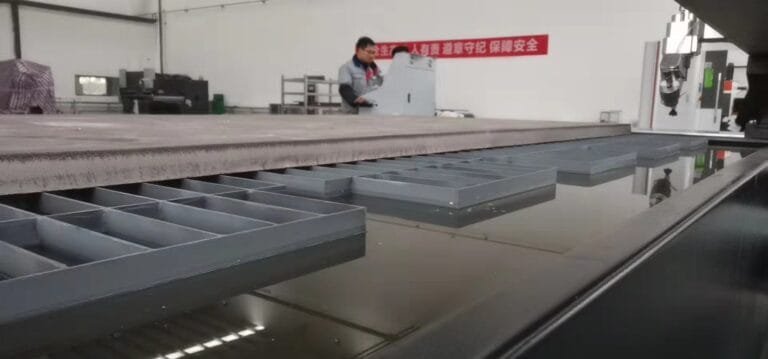

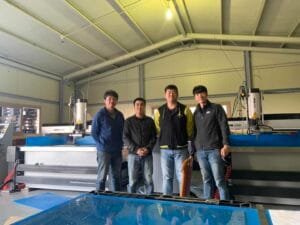

EPC Project Delivered To Glass Processing Industry Owners Of China: Water Jet Cutter – Robot Arm Transporters.

The customer is a decoration and customized furniture company, which uses a water jet cutting machine to make the decorative background walls of hotels.

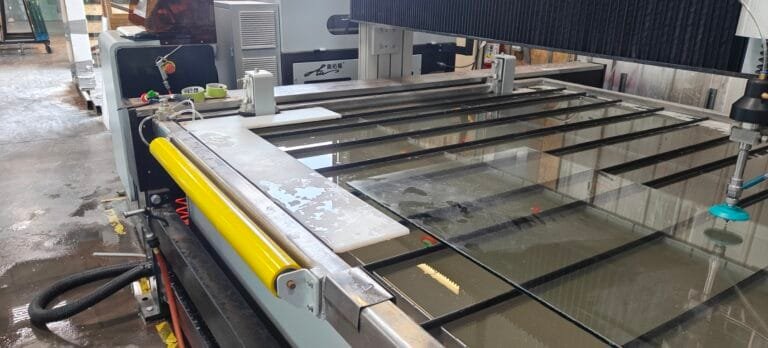

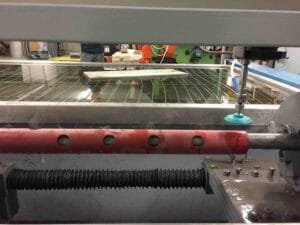

Glass Cutting /Canada

Canada glass cutting project using APW waterjet with roller table and liftable castors, enabling easy loading, smooth transfer, and higher efficiency for large glass panels.

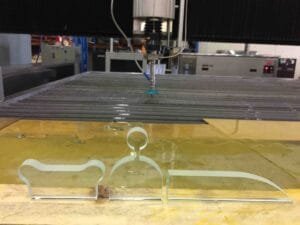

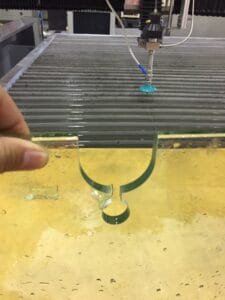

Glass Cutting /China

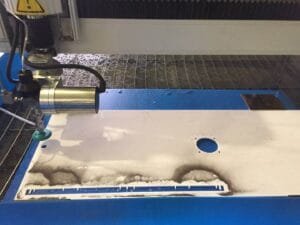

China bathroom glass door clamp cutting using Classical 3020 table with double Z 3-axis heads waterjet, achieving precise cuts, smooth edges, and efficient production for custom glass doors

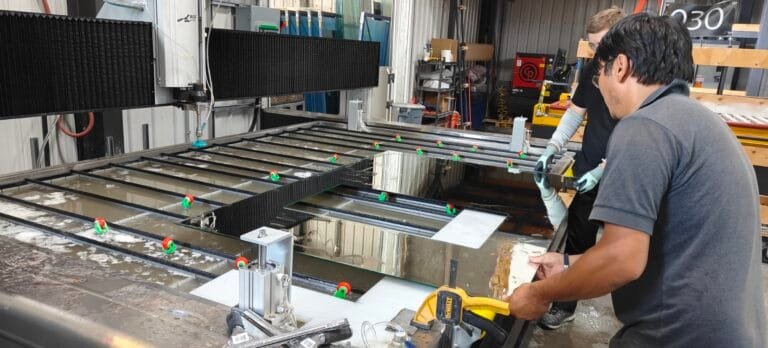

Glass Cutting /Australia

Australia customer cutting large-format glass using gantry 4020 table with classic A15-B pump and 3-axis cutting head, delivering clean edges, high accuracy, and efficient glass processing.

Glass Cutting /Austrialia

Australia customer cutting glass using stainless steel cutting table with dual-intensifier high-pressure pump (one standby) and 3-axis cutting head, achieving precise, clean, and efficient glass processing.

Ceramic Glass Cutting /South Korea

South Korea customer cutting ceramic glass using gantry compact table (2×1.5 m) with small-angle AB 5-axis cutting head, purchasing 2 units in a single order for precise, smooth, and efficient cuts.

Glass Cutting /Canada

Canada customer cutting glass using gantry table with integrated industrial PC and 3-axis cutting head, achieving precise, clean, and efficient glass processing.

Metal Cutting

For a certain aircraft manufacturing factory that needs to cut a titanium plate with a length of 4.5 meters and a width of 2 meters, APW provides it with a 6025 super-large cutting water jet machine.

Iron Cutting /Peru

Peru iron cutting project using waterjet with a small cantilever table and 5-axis head, delivering precise bevel cutting, flexibility, and high efficiency in limited workshop space.

Iron Cutting /USA

USA iron cutting project using a 4020 waterjet table with classical pump and 5-axis head, delivering stable performance, accurate bevel cutting, and reliable results in heavy-duty production.

SS Cutting /Russia

Russia thick stainless steel cutting project using High Frame 4020 table with V6P-55KW pump and 5-axis head waterjet, delivering precise bevel cutting, high power, and efficient heavy-duty performance. flexibility, and high efficiency in limited workshop space.

Special alloy Cutting /China

China special alloy cutting using small cantilever SS water tank table, KMT pump, 5-axis cutting head with laser and terrain sensors for precise, complex shapes and high-accuracy results.

Ti Cutting /China

China customer cutting titanium plates with thickness from 50–120mm, using extra-large 2.5×6m table, dual intensifier high-pressure pump (one standby), and 3-axis cutting head for stable, efficient performance.

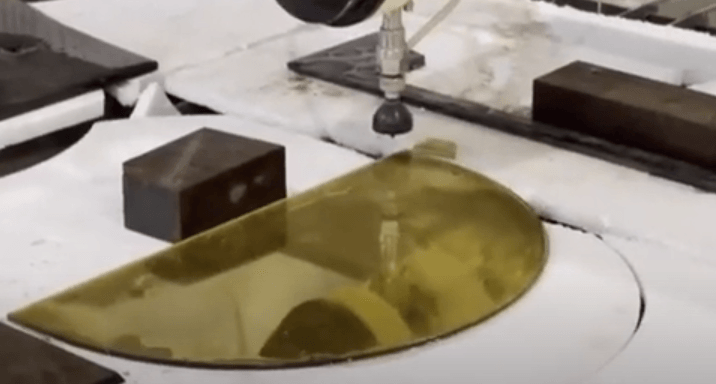

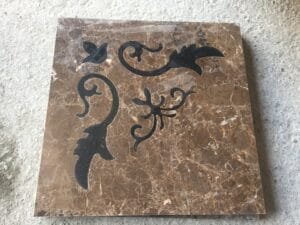

Stone/ Ceramic tile Cutting

The customer cuts ceramic tiles and mass-produces under-counter wash basins. APW provides them with a 3020 basic water jet combo upgraded to an AC 5-axis model.

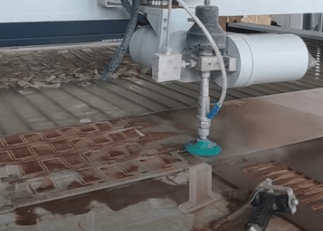

Stone Cutting /USA

USA stone cutting project using a special 3020 small stone cutting table with classical pump and 5-axis head waterjet, achieving precise edges, complex shapes, and high efficiency.

Stone Cutting /Thailand

Thailand customer cutting stone using stone-special waterjet with S4020 floor-mounted tilting table and 5-axis cutting head, achieving precise edges, complex shapes, and high-efficiency stone processing.

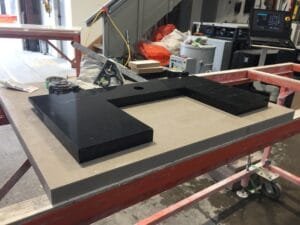

Stone Cutting /New Zealand

New Zealand customer cutting stone for bathroom vanity countertops using gantry 4020 table with 5-axis cutting head, achieving precise edges, smooth surfaces, and high-quality stone fabrication.

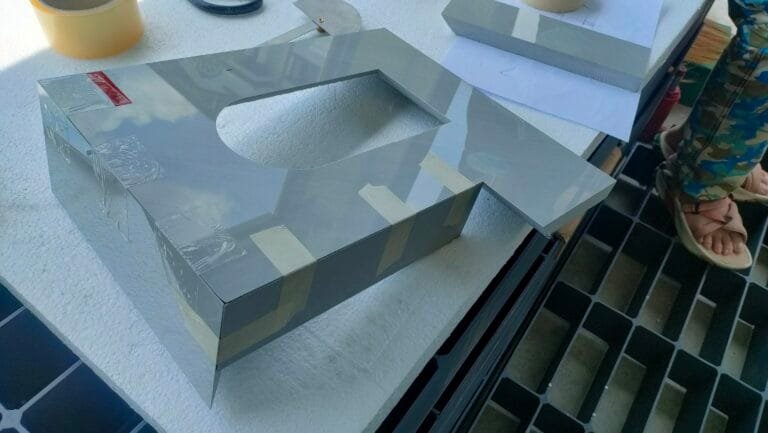

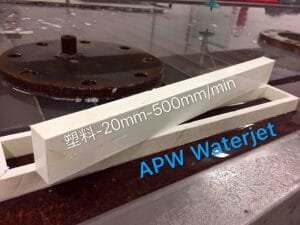

Other materials Cutting with Abrasive / sand

The customer conducts cold cutting on a sandwich material, with the outer layer being PVC plastic and the inner layer being an aluminum corrugated plate, and uses an APW 3020 basic water jet combo for the cutting task.

Silicone Resin Dual-Hole Tube /China

China customer cutting silicone resin dual-hole tubes using cantilever 3-axis Waterjet with servo pump, low-pressure energy-saving pure water cutting, and foam supports to secure tube cores for precise, safe cuts.

Carbon Fiber / Taiwan ,China

Taiwan customer cutting carbon fiber for sports helmets using high-frame table (500mm Z-axis) with compact 1.5×1.5m platform, 5-axis cutting head, and A15×2 dual-intensifier pump (one standby) for stable, precise results.

Acrylic / Austria

Austria customer cutting acrylic sheets using gantry 3015 table with classic A15-B pump and small-angle AB 5-axis waterjet head, achieving precise, clean, and smooth cuts for various applications.

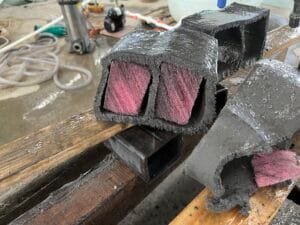

Refractory Materials / Germany

ChatGPT 说:

Germany customer using the best-selling combo 3020BA-A15-B-BP to cut refractory materials, achieving precise, clean, and efficient cuts for high-temperature applications.

Taiwan customer cutting carbon fiber for sports helmets using high-frame table (500mm Z-axis) with compact 1.5×1.5m platform, 5-axis cutting head, and A15×2 dual-intensifier pump (one standby) for stable, precise results.

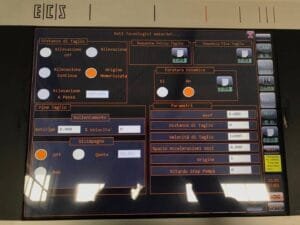

2 in1 tube and sheet / Italy

Italy customer using 2-in-1 plate & tube waterjet to cut multiple materials: plates include plastic, wood, metal, and foam boards; tubes include coated and uncoated iron pipes, as well as stainless steel pipes, achieving precise and versatile cutting.

Pure Water Jet Cutting

APW recently partnered with a major American textile manufacturer seeking an innovative solution for cutting industrial felt. Understanding the client’s need for precision and material integrity, APW provided a state – of – the – art water jet cutter system that uses pure water as the cutting medium.

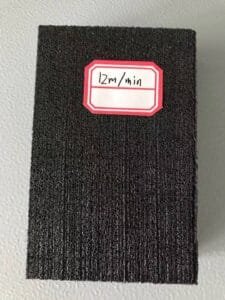

Foam /Italy

Italy foam cutting with PURE WATER and 3-axis head Waterjet, creating precise, custom-fit protective inserts for toolboxes, ensuring secure placement and maximum cushioning.

Engineering Applications of Water Jet

The scope of water jet application cases extends far beyond conventional cutting. Leveraging its leading water jet technology, APW has successfully expanded its applications to critical areas such as fragmentation, tunneling, and emergency rescue.

In fragmentation, APW’s water jet technology efficiently breaks hard rocks and concrete structures in mining and demolition projects. The continuous impact of ultra-high-pressure water flow reduces dust and noise pollution compared with traditional methods, making the process safer, environmentally friendly, and easier to control.

For tunneling, whether in underground construction or metro projects, water jet technology allows precise rock and soil layer removal without the risks associated with traditional blasting. This improves both the stability and efficiency of tunneling operations.

A prime example is the Shenyang Metro construction project, where geological conditions are complex and variable. During tunneling in the alluvial plain, hard rock layers often hinder traditional construction methods, which are inefficient and high-risk. APW integrated its advanced water jet technology into shield machines, creating a unique tunneling system. When encountering rock layers, the ultra-high-pressure water jet breaks rocks with powerful impact, surpassing the limitations of mechanical rock breaking. This approach increased tunneling efficiency by nearly 30% compared to previous methods under similar conditions, while significantly reducing vibration and noise, minimizing environmental and structural impact.

Moreover, the precise control of water jet technology avoids unnecessary rock removal and reduces cleanup burdens, ensuring construction continuity and safety. This solution not only provided robust technical support for the smooth completion of the Shenyang Metro but also serves as a valuable reference for other metro projects in similar geological conditions.

In emergency rescue scenarios, APW’s water jet equipment enables rapid and precise removal of obstacles during disasters such as earthquakes and landslides. Its non-thermal cutting and low-vibration characteristics prevent secondary injuries to trapped individuals, where every second counts.

Through innovative applications, APW continues to push the boundaries of water jet application cases, delivering more efficient, safe, and versatile solutions across multiple industries.

FAQ-water jet application case

1. What is a water jet application case?

A water jet application case is a real-world example showing how APW water jet machines are used to cut materials such as metal, stone, glass, and composites efficiently and precisely.

2. How can water jet application cases help in selecting a machine?

By studying water jet application cases, customers can see which APW model performs best for specific materials and cutting requirements, helping them make an informed purchase.

3. Can APW provide custom application case studies?

Yes, APW can provide tailored water jet application cases to demonstrate solutions for unique industrial challenges and requirements.

4. What industries benefit from water jet application cases?

Industries including aerospace, automotive, construction, stone processing, and glass manufacturing gain valuable insights from water jet application cases.

5. Are the water jet application cases verified by real users?

Yes, these water jet application cases are based on actual customer projects and APW machine performance in real-world industrial applications.