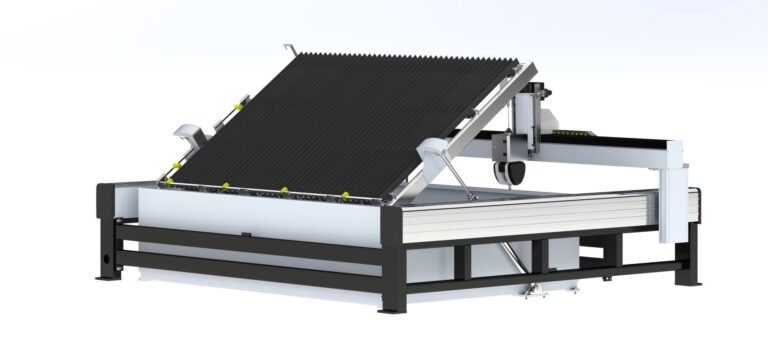

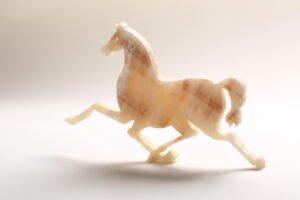

With APW water jet, you can cut all sorts of stuff.

You could start your day slicing up soft, thin rubber gaskets. Then, by the afternoon, you’re cutting glass like it’s no big deal. And when evening rolls around? No problem! Just switch it up and start cutting thick Inconel.

It’s that easy to switch between materials!

If you’re in fabrication, waterjets are a game-changer! They open up so many possibilities for getting creative and really nailing those high – performance jobs.

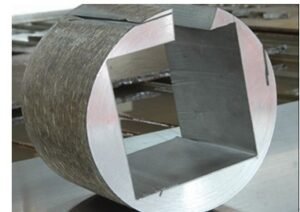

It’s no wonder waterjets are a hit in the fabrication world. Take Flow waterjets, for example. You can cut just about anything with them—any material, no matter how thick it is. Whether you’re a shop owner or a worker, waterjets fit your needs like a glove. Think about it: one day you might be working on super – precise stainless steel or aluminum projects, and the next, you could be cutting through thick armor plates or weldments. No other cutting tech can do all that. Waterjets are the go – to choice for almost any fabrication job out there.

Fabrication work is always changing. You never know what project will land on your desk next. But that’s where waterjets really shine. They’re crazy flexible, so you can easily switch gears and handle whatever job comes your way. With a waterjet in your shop, you’ve got a reliable tool that gets the job done, no matter how different one project is from the next.

water jet cutting simples

water jet application FAQ

1. What are the main water jet applications in manufacturing?

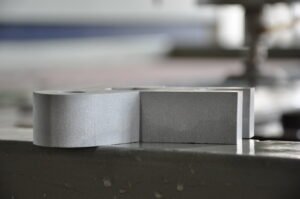

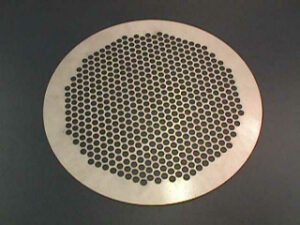

Water jet applications in manufacturing include precision cutting of metals, composites, glass, and ceramics. They are widely used because they produce clean edges without heat damage or material distortion.

2. How is water jet application different from laser cutting?

Unlike laser cutting, water jet applications use cold cutting technology. This means no heat-affected zones, making it safer for materials like stainless steel, aluminum, and heat-sensitive composites.

3. What industries benefit most from water jet applications?

Key industries include aerospace, shipbuilding, automotive, stone processing, and glass manufacturing. These sectors value the versatility and precision of water jet cutting for complex parts and delicate materials.

4. Can water jet applications handle thick materials?

Yes. Water jet cutters can process materials up to several inches thick, including hardened steel, granite, and laminated glass, without compromising edge quality.

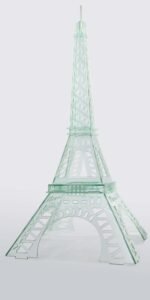

5. Why choose water jet applications for glass cutting?

Glass cutting with water jet applications is highly effective because it avoids cracking and chipping. The cold cutting process ensures smooth edges, even on intricate shapes or delicate glass panels.