water jet accessories also called opitons

Options is the way that create your own water jet cutter

1. Table Sub-Class

Features

Improve loading and unloading efficiency: Reduce manual operations and improve production efficiency through automated devices.

Adapt to a variety of workpieces: Provide a variety of loading and unloading solutions , suitable for workpieces of different sizes and weights.

Enhance operational convenience: optimize the equipment usage experience and reduce the labor intensity of operators.

Application Scenario

Processing of large workpieces: such as stone, metal plates, etc., requires automatic loading and unloading through a flip device or a semi-floor flip device.

High-efficiency production: Suitable for processing scenarios that require frequent workpiece replacement, such as automobile parts manufacturing.

Processing of special materials: fragile materials such as glass and ceramics require special devices to achieve smooth loading and unloading.

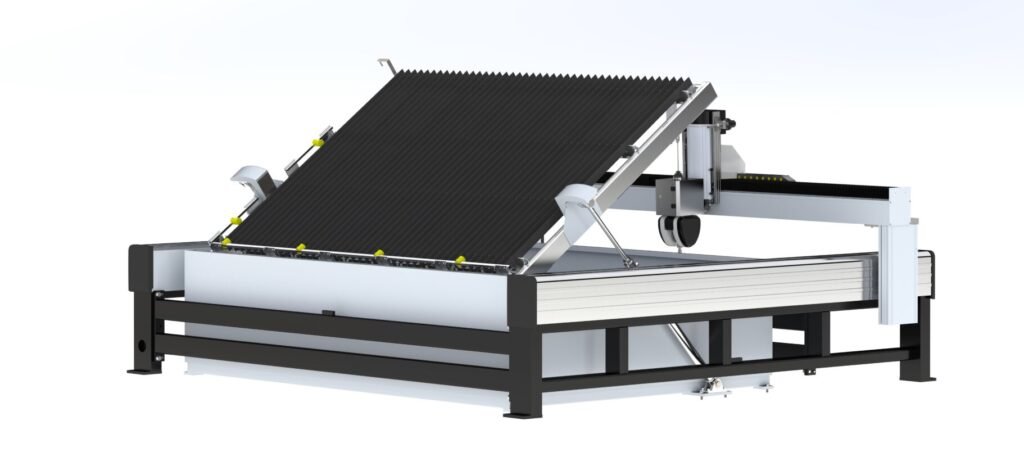

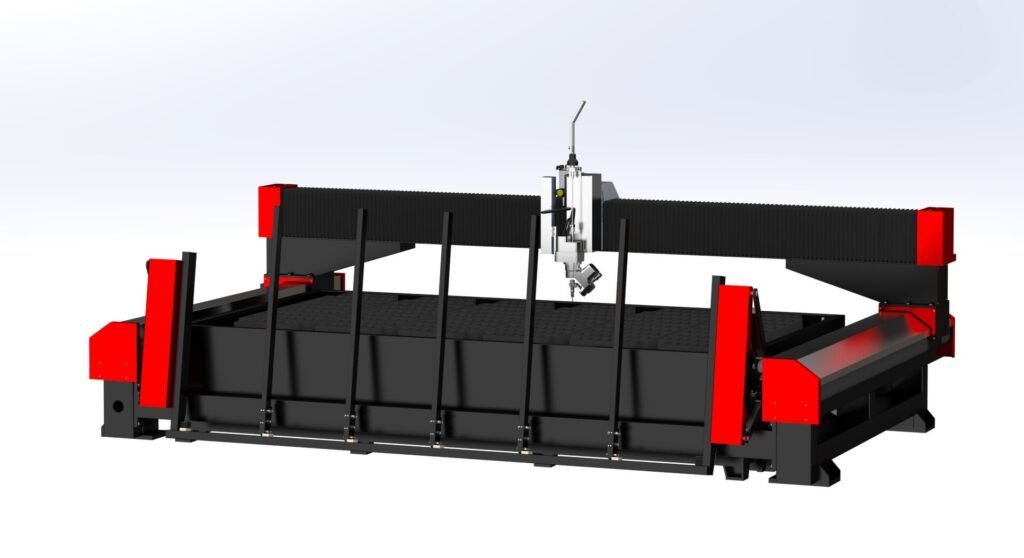

Floor-standing turning device

suitable for loading and unloading large workpieces, with a maximum lifting weight of up to 1000kg.

Semi-floor flip device

suitable for medium-sized workpieces, easy to operate, and suitable for scenes where workpieces are frequently replaced

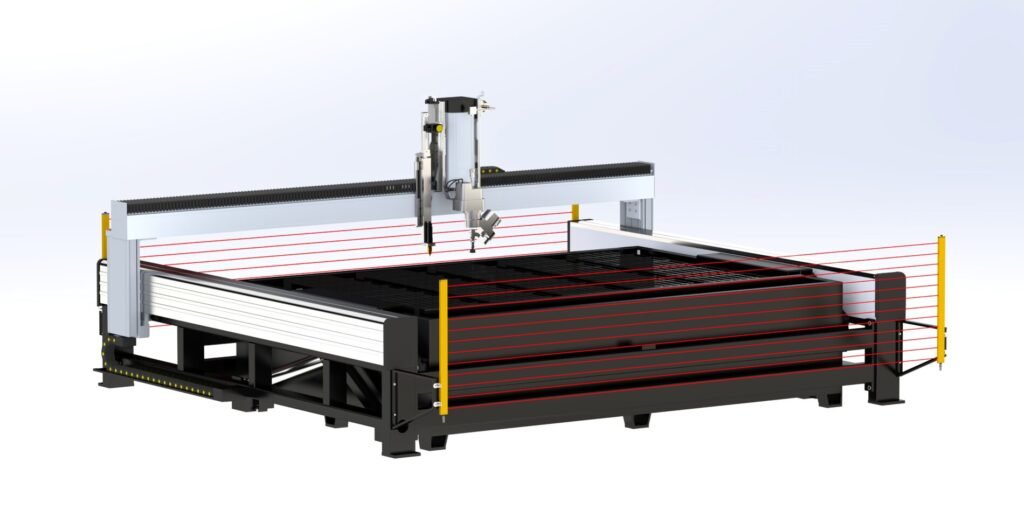

Safety light curtain

protect the safety of operators and prevent accidents caused by mis operation

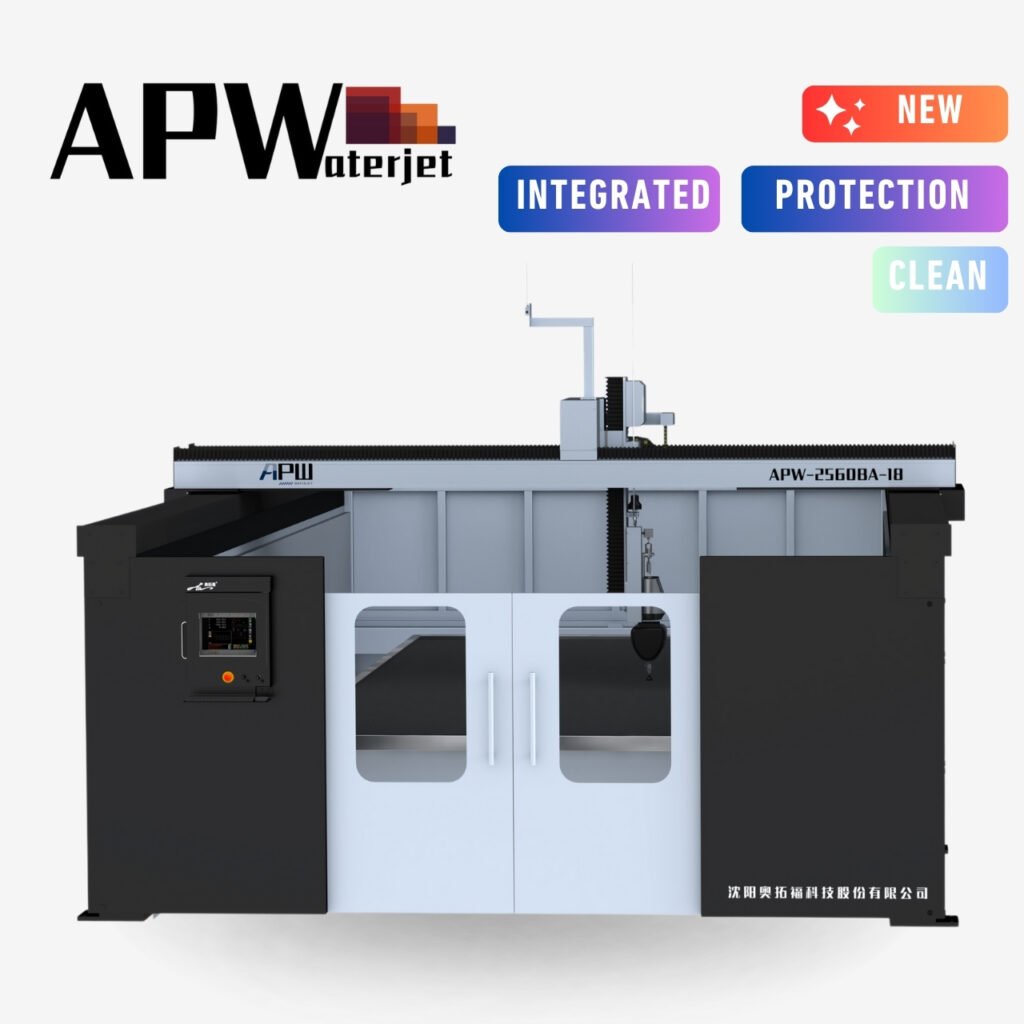

Protection Coat

Whatever normal Z-travel or high Z-travel table, you could update your table, the IPC is hanging on protection coating at same time.

2. Head Sub-Class

Features

Improve cutting efficiency: realize synchronous or asynchronous cutting by increasing the number or function of the cutter heads.

Adapt to complex processing: Provide a variety of cutter head configurations to meet the cutting needs of different materials and shapes.

Enhanced cutting accuracy: Equipped with follow-up mechanism and anti-collision device to ensure the stability and accuracy of the cutting process.

Application Scenario

High efficiency cutting: suitable for scenarios that require fast cutting, such as metal sheet processing.

Complex shape processing: complex shapes such as 3D surfaces and grooves require multi-axis tool heads or follow-up mechanisms.

High precision processing: such as aerospace parts, medical equipment, etc.,which require high-precision cutting and anti-collision protection

About 5-axis Head

PLEASE NOTICE:

It’s different between 3-axis table and 5 axis table on electrical part and control system software, means that quite hard to transfer 3-axis to 5-axis. The Best thing is make right decision at very beginning, please feel free to talk with APW Water jet sales who have more than 10 years and be very kind and helpful.

AB 5-axis

up to 12° angle

taper compensation

metal vertical cutting

tile chamfer cutting

AC 5-axis

up to 89° angle

3D cutting

complex curve, most cutting possibilities

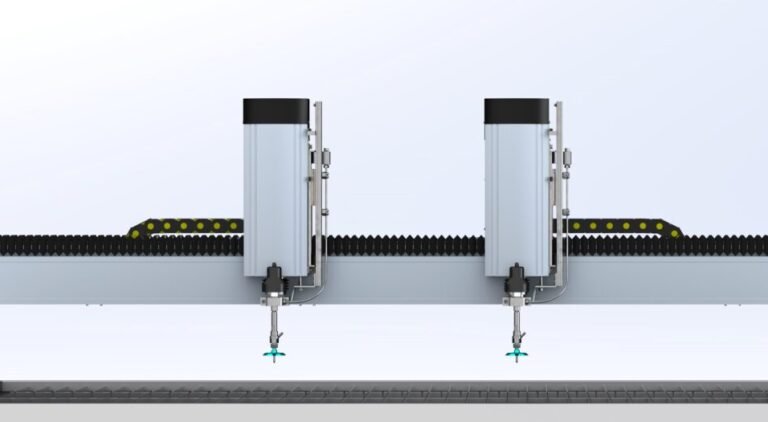

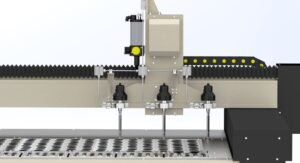

Z axes or multiple

cutting heads on the same beam to achieve synchronous or asynchronous cutting

and improve cutting efficiency.z

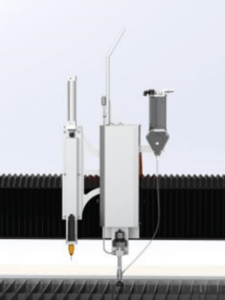

Laser height measuring device

non-contact height measurement, adapting to complex curved surface processing and ensuring cutting accuracy.

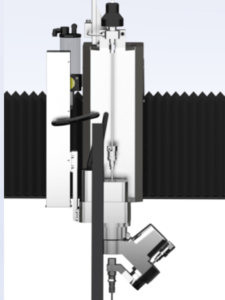

Follow-up mechanism

automatically adjusts the height of the cutter head to adapt to uneven surfaces and avoids collision and damage to the cutter head

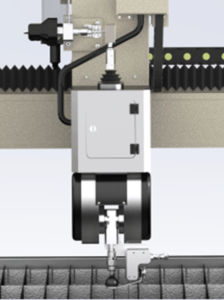

Anti-collision device

In case of misoperation or program problems, the machine will automatically stop and reset to protect the cutter head and workpiece

Composite mechanical drill bit

Pre-drill holes in composite and metal materials to improve cutting efficiency

3. Support Sub-Class

Features

Optimize the processing environment: reduce pollution and equipment wear during processing through sand removal, cooling and other devices.

Improve equipment life: Equipped with cooling system and sand removal device to extend equipment life.

Enhanced operational safety: Equipped with safety devices, such as safety light curtains, to protect the safety of operators.

Application Scenario

High environmental protection requirements: such as food processing, medical equipment manufacturing, etc., need to reduce pollution

during the processing.

High equipment life requirements: For example, high-power cutting equipment needs to be equipped with a cooling system and sand removal device.

High operational safety requirements: For example, processing workshops with dense personnel need to be equipped with safety gratings and other devices.

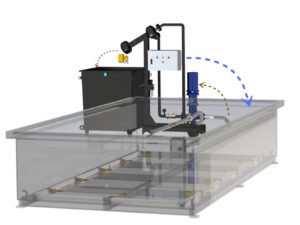

The online sand removal system

It can automatically separate the sand and water produced by cutting, reduce pollution and extend the life of the equipment

Sedimentation tank:

The sludge is gradually clarified through gradient filtration grids.

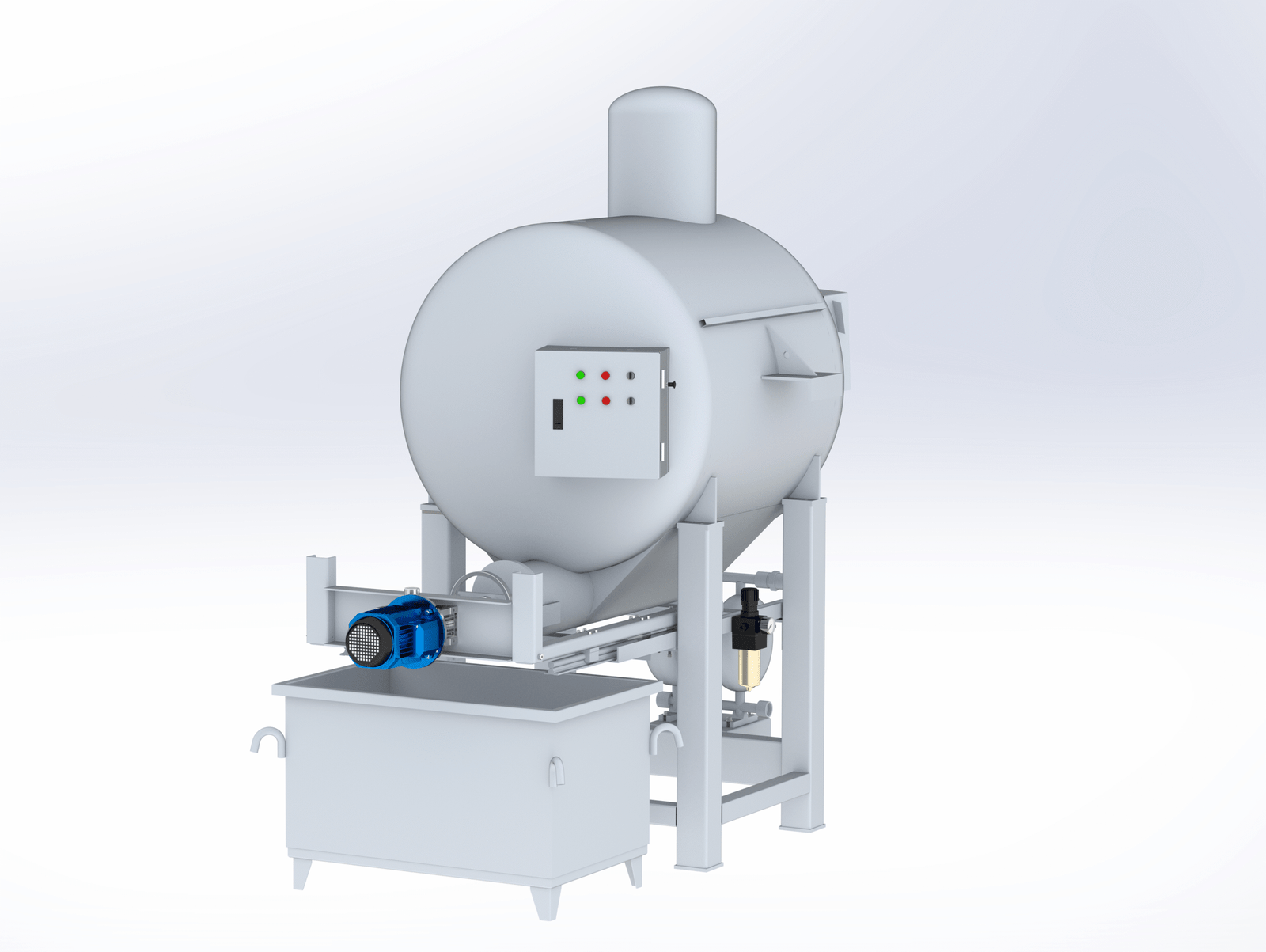

sand removal machine

It can suck the sludge out of tank. That could be better if work with sedimentation tank.

Cooling system

such as air cooler, water cooler, oil cooler, to reduce the operating temperature of equipment and improve stability

Water softener

Mainly used for water softening, protecting equipment, improving cutting quality and reducing maintenance costs, suitable for high-precision cutting and areas with poor water quality.

Remote controller

provides remote operation and manual control functions, improves operational flexibility and safety, and is suitable for complex workpiece processing and multi-person collaboration scenarios

Barcode scanner

quickly identify material information, realize automated data input, improve production efficiency and quality traceability, and is suitable for large-scale production and material diversity scenarios