Fast running+saving energy+drill

APW-GS3020-a22s-bp

> Table Size: 3m(X axis)*2m(Y axis)

> Pump power: 23.9/ 32.8 / 38.8 KW, 3.7L/min HP Flow

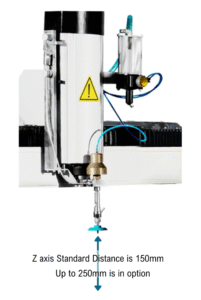

> Cutting Head: 3 Axis, 150mm Z-travel, 0.33 Nozzle, Pure water or abrasive swifts flex

Application: most cutting industries

Customer industries: Fast Production Rhyth / Sensitive to energy prices / Multiple drilling operations / require time-consuming loading

Choose Reason: rack& pinion Drive way / Fast Running cutting head / Servo motor / super low power running cost during intensifier breaking

Fast Running Water jet Cutter with Drill Details

Table

- suit for most of raw materials

- 3m(X axis)*2m(Y axis)

- Cutting Accuracy: 0.1mm

- Repeatability: 0.03mm

- Traverse Speed: 30 m/min

- Load Capacity: 500KG/㎡

- Bridge like axis runway and Separate frame and water tank keep stability and reduce the impact on cutting accuracy

- 2 sides uploading

- More Size(X*Y, m): 2012 / 2015 / 3020 / 2040 /2060

Pump

- Model

- A22S-24 (23.9KW)

- A22S-32 (32.8KW)

- A22S-37 (38.8KW)

- Power(KW): 23.9/32.8/38.8/45/75

- Plunger Pump Brand: Rexroth

- Plunger Pumps Count: 1

- Intensifiers Count: 1(S)

- HP Water Flow(L/Min): 3.7(S)

- Nozzle(Mm): 0.26/0.3/0.33

- HP Water Max Pressure(MPa): 360/380/413

- Control Display: Have(S)

- Size(Mm): 1715*1045*1272 (S)

- Weight(KG): 1100

Head

- 3 axis head

- with dirll

- 150mm Z-travel

- pure water or abrasive swifts flex

Friendly

- The water tank bed is integrated, which reduces the need for regular precision adjustments for novices.

- The rack and pinion drive reduces vibration during high-speed movement.

- Equipped with a pneumatic drill to assist in drilling, it reduces frequent switching between high and low pressures and extends the life of the pump.

Feedback

- Very suitable for mass production.

- A good choice for users in areas with high energy prices.

- Increase profits without increasing working hours.

high light

- Fast Running Head ,High Precision, Easy to Operate:The servo motor enables automatic pressure adjustment. Simply set the parameters, and it can stably handle high – demand processing tasks, reducing defective products.

- Efficient, Precise, and Fast Delivery:The gear – rack platform has a speed of up to 30m/min and a positioning accuracy of ±0.02mm. No manual calibration is required, increasing the processing efficiency by 40%.

- Energy – Saving and Low Maintenance:The EtherCAT bus enables coordinated operation, reducing energy consumption by 30%, minimizing malfunctions, and lowering maintenance costs.

| Structure Type | Bridge Style |

| X Axis Travel mm | 3000mm |

| Y Axis Travel mm | 2000mm |

| Z Axis Travel mm | 150mm |

| Way of Drive | AC Servo |

| Power Supply | AC 220V, 50Hz/60Hz |

| Total Power | <6.79HP / 5KW |

| Load Capacity | 500KG/m2 |

| Control Accuracy | ±0.01mm |

| Positioning Accuracy | ±0.04mm/1000mm |

| Repeatable Positioning Accuracy | ±0.03mm |

| Cutting Speed | <3m/min |

| X axis Max. Moving Speed | 30m/min |

| Y axis Max. Moving Speed | 30m/min |

| Z axis Max. Moving Speed | 1m/min |

| Table Material | Stainless steel |

| Thickness | 3mm |

| More Table Sizes Available | |||

| Bridge-BA | X Axis Travel mm | Y Axis Travel mm | Z Axis Travel mm |

| 2012BA | 2000 | 1200 | 150 |

| 2015BA | 2000 | 1500 | 150 |

| 2040BA | 2000 | 4000 | 150 |

| 2060BA | 2000 | 6000 | 150 |

| 2080BA | 2000 | 8000 | 150 |

Pump

| General | |

| Main Motor Power | 23.9/32.8/38.8/45/75 KW |

| Max. Working Pressure | 360/380/413.7Mpa |

| Continuous Working Pressure | 360-380Mpa |

| Max. Water Discharge | 3.7/7.4 L/min |

| Max. Orifice Available | 0.26 /0.3 /0.33 /0.46 mm |

| Power Supply | 380V/50Hz/3PH |

| Noise Level | 75db(A) |

| Size | 715*1045*1272 (S) / 2100*1370*1510(W) |

| Weight | 1100 / 1400 / 1700 KG |

Head

| Type | 3-axis |

| Z axis Travel | 150mm |

| A axis tile angle | 0 |

| B axis tile angle | 0 |

| C axis tile angle | 0 |

| dirll | peneumatic or electric |

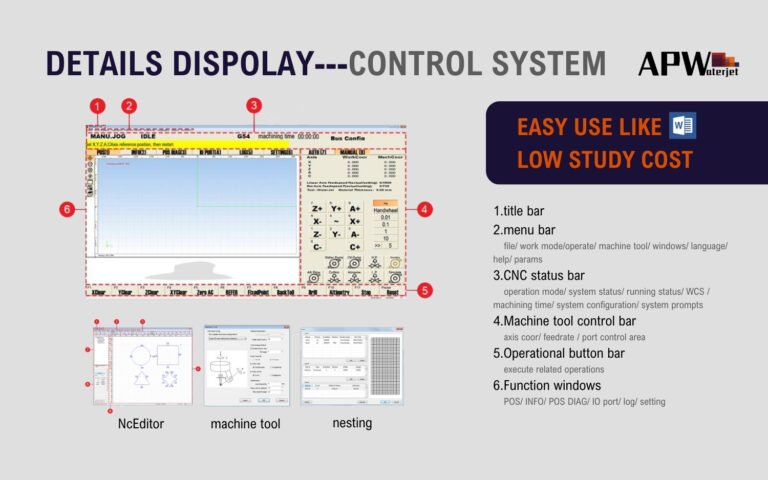

Control System

| Name | NC-Studio |

| Features | |

| Easy use | |

| Low study cost | |

| Multiple O-Point settings | |

| Built-in CAM, NCEditor | wear-and tear part management |

| Supports multiple process settings | bridging/micro-linking/chamfering/ beveling/sorting/ vertical |

| supports the linkage of various auxiliary functions | laser height detection, edge-finding, barcode scanner reading, drill bit lifter |

| ceramic sink cutting treatment | visual contour extraction |

| machine tool management | |

| nesting |

| Main windows | |

| Title bar | |

| Menu bar | file/workmode/operate/machine tool/windows/language/help/params |

| CNC status bar | operation mode/ system status/ running status/WCS/ machining time/ system configuration/ system propts |

| Machine tool control bar | axis coor/ feedrate/ pot control area |

| Operational button bar | execute related operations |

| Function windows | POS/INFO/POS DIAG/ IO port/log/setting |

Auto Abrasive Delivery System

| General | |

| Max. Inlet Air Pressure | 0.8Mpa |

| Min. Inlet Air Pressure | 0.2Mpa |

| Abrasive Capacity | 270Kg |

| Operating Air Flow | 0.5 m3/min |

| Volume | 590x590x1340mm |

| Power Supply | GC24V |

| Features |

| Self-feeding Control |

| Self sealing |

| Air Valve to prevent jams and breakages |

| Use non-metallic sensor to work acutely and long work life |

No.1

The biggest water jet factory of china , 300 sets of water jet per year

Full Production Chain

design-machining-assembly-QC-warehousing-sale-technical support

1800+ Fans

5000+ Water jet Cutters for 1800+Customers in 60+ Countries

No-Stop Forward

Optimization, new types and new patents for water jet every year