Classical Water Jet Solutions from China

Water jet China solutions from APW offer high precision, stable performance, and versatile applications across industries such as stone, glass, and metal processing.

As one of the leading suppliers of classical water jet combos in China, APW ensures reliable and efficient cutting technology for factories worldwide.

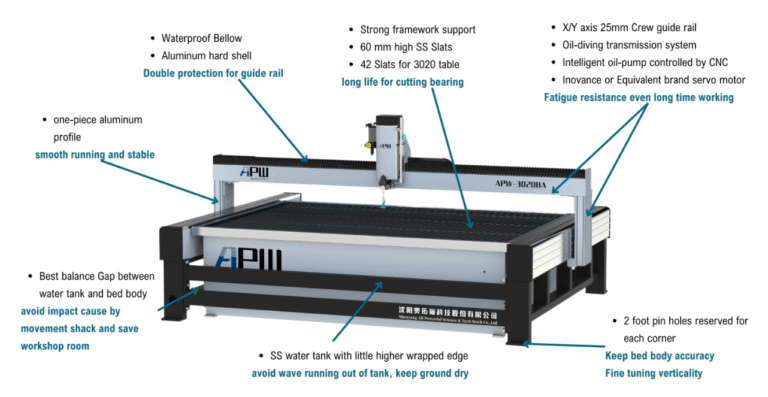

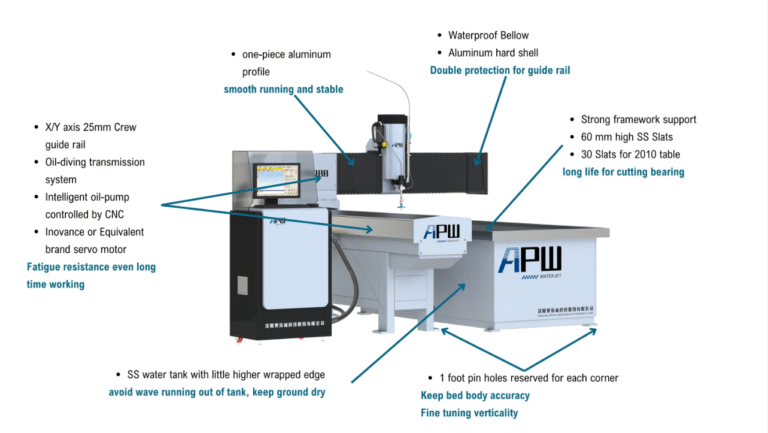

A best-selling product on the market, it adopts a gantry structure and has high stability

simple and economical structure, suitable for open space operation, easy to load and unload

6 REASONS WHY IT'S THE BEST SELLING OF WATER JET

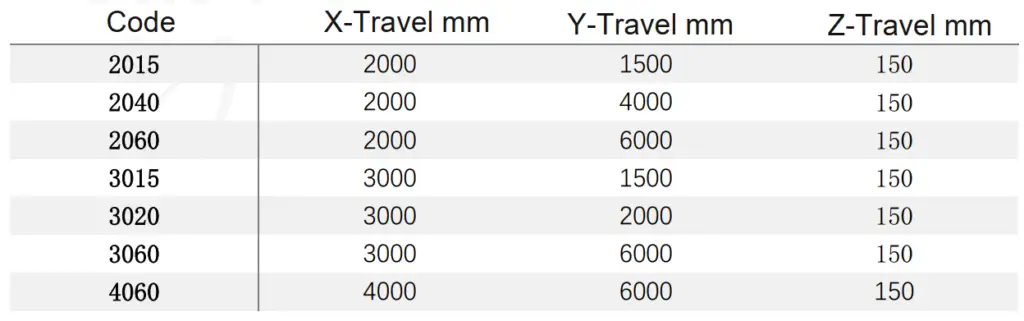

Table

- suit for most of raw materials

- 3m(X axis)*2m(Y axis)

- Bridge like axis runway and Separate frame and water tank keep stability and reduce the impact on cutting accuracy

- 2 sides uploading

Pump

- Classical pump Tech-Data

- 37KW power; 3.7L/min Flow

- 0.33mm nozzle(jet diameter)

Head

- 3 axis head

- 150mm Z-travel

- pure water or abrasive swifts flex

Cost

- 5 Parts of equitment combo are all functional

- Best-selling means that as a mass-produced product, it has a fair price, and its accessories and consumables are easy to purchase at reasonable prices.

- Being the most classic product means that the return on investment is very substantia

Feedback

- Mature technology is capable of handling the vast majority of tasks

- Nearly no complaint

- Best market feedback

Friendly

- Fresh man friendly

- easy operation, easy maintenance

- The Gantry series waterjet cutting machine adopts the classic gantry structure and is a bestselling product on the market. Its high-precision ball screw drive and customized nut mechanism ensure extremely high precision and stability during the cutting process. The water tank and protective device are made of all stainless steel, with a double-layer protection design to effectively resist corrosion and extend the service life of the equipment. The intelligent lubrication system can automatically lubricate the transmission system according to the CNC settings to ensure long-term and stable operation of the equipment. In addition, the reinforced structural design of the crossbeam and side support further improves the overall rigidity of the equipment, making it perform well in high-intensity processing.

- It is suitable for application scenarios with extremely high requirements for processing accuracy, such as aerospace parts, high-end metal sheet processing, etc. It is an ideal choice for users who pursue high stability and high precision.

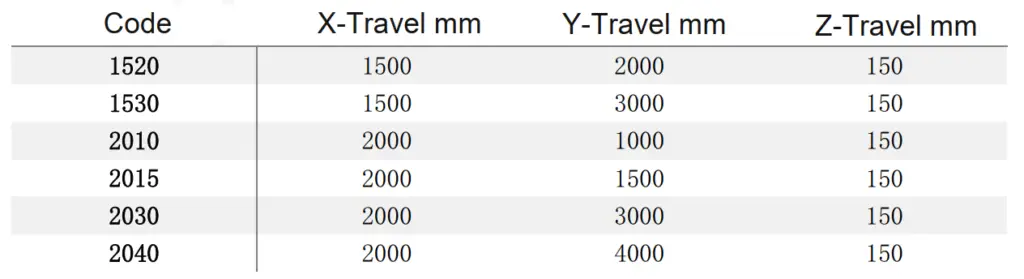

Table

- small room choice

- 2m(X axis)*1m(Y axis)

- Arm like cantilever design and Separate frame and water tank keep stability and reduce the impact on cutting accuracy

- 3 sides uploading

Pump

- Classical pump Tech-Data

- 37KW power; 3.7L/min Flow

- 0.33mm nozzle(jet diameter)

- suit for most of raw materials

- 3m(X axis)*2m(Y axis)

- Bridge like axis runway and Separate frame and water tank keep stability and reduce the impact on cutting accuracy

- 2 sides uploading

Head

- 3 axis head

- 150mm Z-travel

- pure water or abrasive swifts flex

Cost

- 5 Parts of equitment combo are all functional

- Best-selling means that as a mass-produced product, it has a fair price, and its accessories and consumables are easy to purchase at reasonable prices.

- Being the most classic product means that the return on investment is very substantia

Feedback

- Mature technology is capable of handling the vast majority of tasks

- Nearly no complaint

- Best market feedback

Friendly

- Fresh man friendly

- easy operation, easy maintenance

- The cantilever series waterjet cutting machine is famous for its simple and economical structural design, which is particularly suitable for the operating environment of open space. Its single-support cantilever structure is not only convenient for loading and unloading operations, but also allows free expansion of the travel in the X-axis and Z-axis directions to meet diverse processing needs. The workbench is made entirely of stainless steel and is paired with a three-layer water tank grille, which is not only highly corrosion-resistant but also easy to replace and has a long service life . In addition, the Z-axis is made of aviation aluminum alloy, which is light and rigid, and has little impact on the beam load, further improving the operating accuracy and stability of the equipment.

- It is widely used in small and medium-sized processing workshops, especially suitable for users with strict requirements on space and cost. It can effectively improve production efficiency and reduce equipment investment costs.

what you can update basic combo?

Advanced water jet china

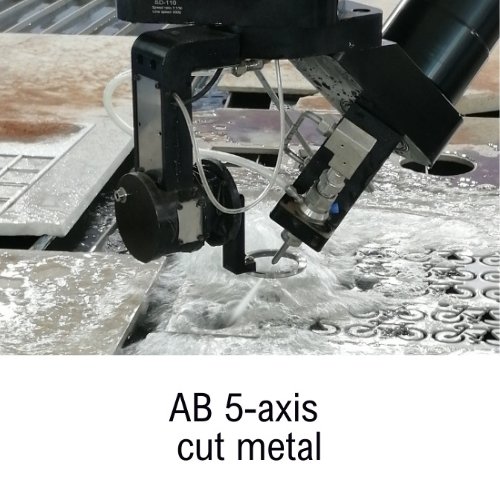

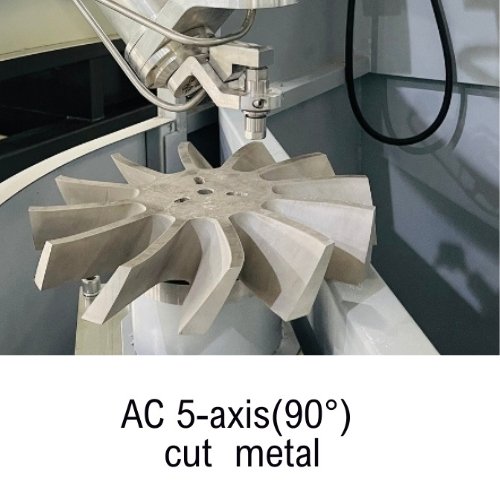

How about 3D Cutting?

AB 5-Axis can turn small angle about 12° for compensation which can form a vertical cutting surface. Metal or ceramic tile for mosaic always is cut by it.

AC 5-axis has 2 type heads. Both can turn big angle, max. to 89°. You can cut complex shapes or bevel by it.

Options of water jet china

Using options on your water jet cutter could increase your effect, protect operators, keep clean or cut more easily.

small cost, big help.

- lifter

- the 4-th axis

- the 6-th axis

- safety light curtain

- protection coating

Head-related expansion

- multi-head

- multi-Z axis

- anti-collision device

- drill

- laser height Detector

stream-related expansion

- water softener

- sand removal system

- cooler

other expansion

- remote controller

- barcode scanner

more about APW water jet that help you start your business?

FAQ

1. Why choose a water jet China cutter from APW?

Choosing a water jet China cutter from APW ensures competitive pricing, reliable performance, and full technical support. APW is one of the top water jet China manufacturers, offering classical and advanced cutting machines.

2. What industries in China use water jet China machines the most?

Industries across China, including stone processing, glass fabrication, and metal manufacturing, widely adopt water jet China machines for their precision and versatility.

3. How does APW ensure quality in its water jet China machines?

APW follows strict production standards for all water jet China machines, including CE/ISO certification. Each water jet China cutter undergoes rigorous testing to guarantee durability and high performance.

4. Can APW export water jet China machines outside of China?

Yes, APW exports its water jet China machines to over 100 countries, providing technical support, spare parts, and training to ensure smooth operation worldwide.

5. What makes APW stand out among water jet China suppliers?

APW is the largest water jet China manufacturer, with two production bases, patented technologies, and over 20 years of experience delivering reliable water jet China solutions globally.

6.Advantages of Choosing APW Water Jet from China

Cost-Effective Solutions – Competitive pricing compared to international brands while maintaining high quality.

Strong Manufacturing Base – Over 20 years of experience with two large production facilities in China.

Complete Product Line – From entry-level to advanced 5-axis water jet systems, covering multiple industries.

Proven Export Capability – Machines delivered to 100+ countries with stable supply chain and logistics support.

Certified Quality – CE, ISO, and patent-protected technologies ensure reliability and durability.

Comprehensive After-Sale Service – Global technical support, spare parts availability, and training services.

Flexible Customization – Tailored solutions to meet the needs of small workshops, medium enterprises, and large factories.