Compare Water Jets

APW Cutting Machines Overview

Here, you can easily compare water jets using the provided data.

Please pay special attention to the notes highlighted in orange. We will explain the significance of this information and offer practical industrial advice, helping you quickly and clearly select the most suitable water jet cutting machine for your needs.

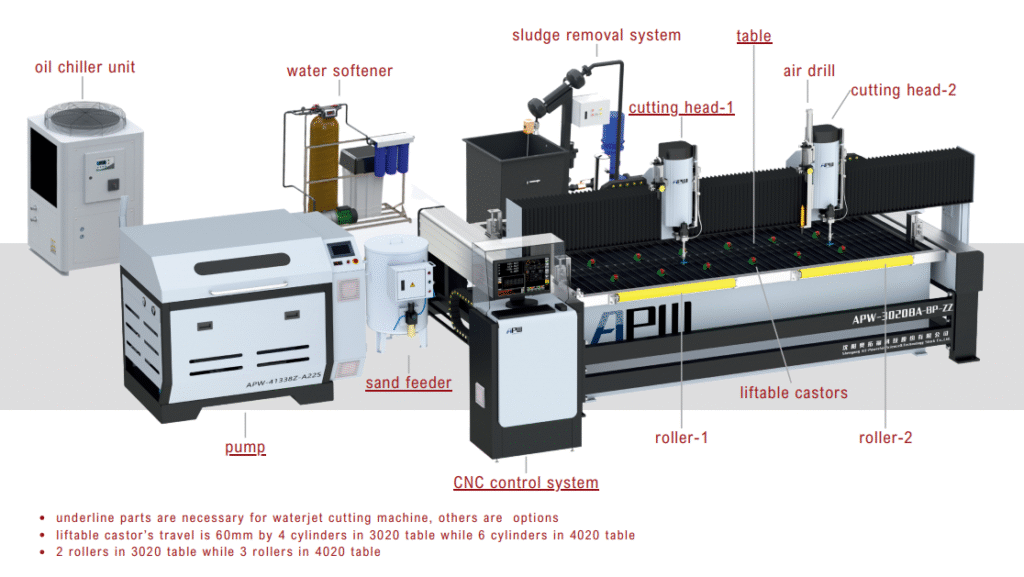

cutting table

carry your simples

pump

create HP water to cut

cutting head

determine how complex workpieces can be cut

CNC control

input your CAD file

options

the beginning of customizing your own water jet

Compare Water Jets From 5 Factors Above

table typles---compare water jets

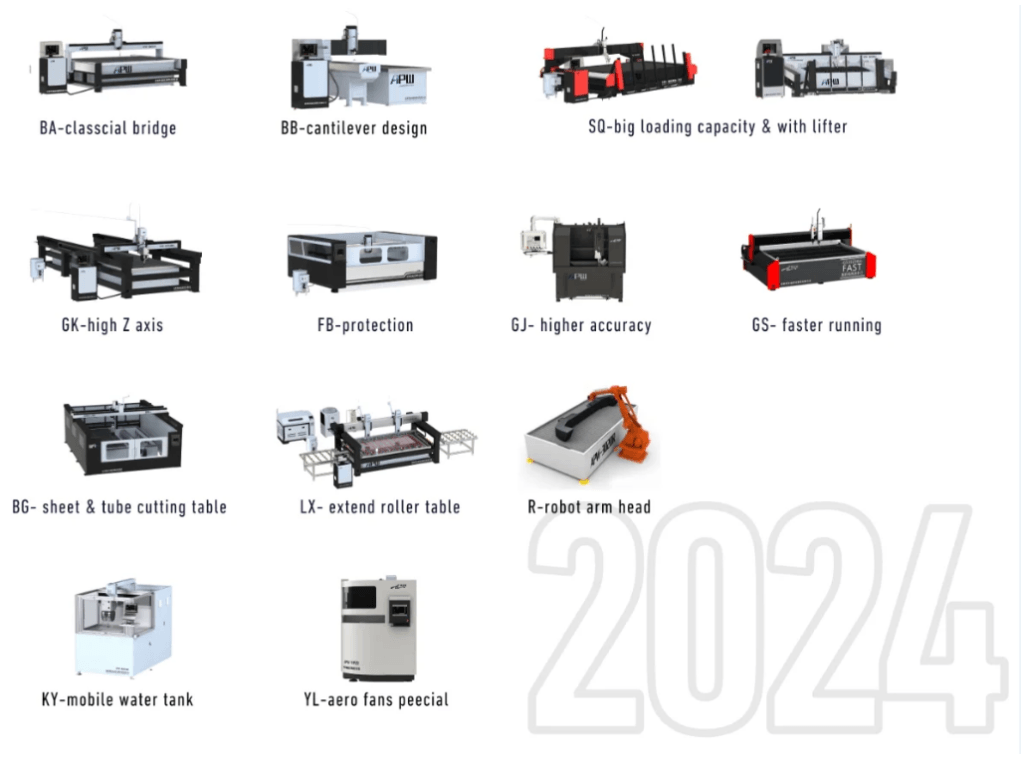

Bridge Style

cantilever style

coating style

robot sytle

For water jet cutting table, the bridge type is the most common, classic and relatively stable style. Due to structural rigidity issues, the X-axis (horizontal direction) is usually 3 meters or 4 meters. If it is longer, it will cause the cutting head to vibrate during high-speed operation, affecting the accuracy.

The advantage of the cantilever type is its open structure, allowing loading from three sides, and it has a smaller floor area for a platform of the same size. The water tank is completely independent. Since it is supported on only one side, the X-axis is usually 2 meters.

The coating can effectively prevent splashing, protect against the danger caused by accidental contact by personnel, and it also appears to be more integrated and aesthetically pleasing. However, its disadvantage is that it takes up more space and is more expensive.

The robot replaces the traditional crossbeam for carrying the cutting head, which is more modern and accurate. But the cost of this advanced feature is a higher learning cost, because every movement needs to have a pre-set program. At the same time, the recoil force when the high-pressure water is ejected also poses a challenge to the accuracy of the robot.

pumps---compare water jets

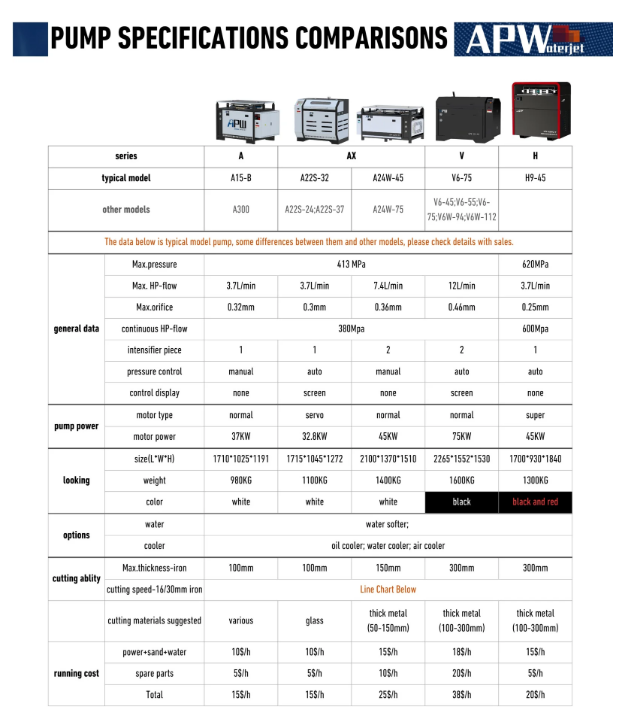

Classical A15

37KW-380MPa-3.7L/min

Advanced A16*2

single or dual intensifiers

Save energy A22S

servo motor

Powerful V6

37/45/55/75KW

3.7/6/8.4L/min

hyper-high pressure H9

620MPa

For water jet cutting pumps,The A15 series is the most classic and best-selling one. Its technical parameters and selling price are well-balanced, enabling maximum benefits. If you don’t have any special requirements, it is capable of handling the cutting of glass, stone, or composite materials.

The A16*2 series is an upgraded version of the A15 series. It has an additional intensifier. You can choose to have the two intensifiers work simultaneously to increase efficiency, or you can use one as a backup to prevent downtime during heavy workloads.

The A22S series uses a servo generator. As we know, the time for loading and unloading materials and the idle running time of the cutting head account for a large portion of the waterjet cutting process. With this, the electricity consumed during the standby time can be saved, thus reducing your electricity costs. If you are cutting glass, you can choose the A22S series water cutting pump with a lower voltage, because glass cutting doesn’t require too high a pressure. Excessively high pressure can easily cause the edges of the glass to shatter.

The V6 series is specifically developed for metal cutting, especially for the cutting of thick metals (more than 100mm). The high-power motor makes the intensifier more efficient. Paired with a large flow rate, it endows the water jet with greater capabilities in piercing, erosion, and cutting. If you have very high requirements for the edge quality when cutting thick metals, it is recommended that you choose the H9 high-pressure pump with a 620MPa intensifier. The ultra-high pressure and small flow rate generate a greater pressure, making it easier to drill holes and obtain high-quality edges.

heads' function---compare water jets

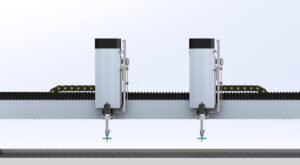

3 axis head

no angle cut

AB 5 Axis head

small angle cut ±12°

AC 5 Axis head

big angle cut ±89°

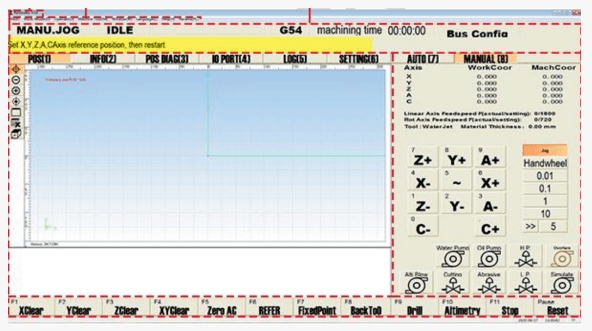

Generally speaking, the control software does not include the function of converting 3D to 2D G CODE. You need additional software to achieve this, so you should communicate with the salesperson about your most complex drawings. In addition to the control programs related to the conventional waterjet cutting process, the control software also includes simple CAM and nesting functions. Of course, if you install other accessories, corresponding control buttons will be added to the control software. Each waterjet control software has its unique features. Some small functions are very convenient for operators, which not only improve the efficiency but also reduce the error rate and increase the success rate of waterjet cutting.

Multiple O-points settings

built-in CAM; wear&tear part management;

supports multiple process setting (bridging, micro-linking, chamfering, beveling,sorting,vertical)

supports the linkage of various auxiliary functions ( laser height detection, edge-finding, barcode scanner reading, drill bit, lifter)

ceramic sink cutting treatment (visual contour extraction)

1. Why should I compare water jets before purchasing?

Comparing water jets ensures you choose the machine that best fits your material, precision, and production requirements.

2. What factors are important when comparing water jets?

Key factors include cutting speed, maximum pressure, nozzle type, abrasive usage, maintenance, and energy efficiency.

3. How do APW water jet models differ?

Each model differs in pressure capacity, cutting size, portability, and suitability for different materials, allowing you to compare water jets effectively.

4. Can I compare water jets for different industries?

Yes, comparing water jets helps identify which machine is best for stone, metal, glass, or composite material processing.

5. How does comparing water jets improve production efficiency?

Selecting the right water jet reduces material waste, ensures precision, and increases overall cutting speed, maximizing ROI.