CNC Water Jet Cutting: Transforming Fabrication

CNC Water Jet Cutting has revolutionized fabrication processes across industries, combining precision, speed, and flexibility. From metals and stone to glass and composite materials, CNC-controlled water jets allow manufacturers to cut complex shapes efficiently and accurately.

For more guidance on selecting the right system, see our article on Choosing the Right Water Jet Cutter for Your Workshop. You can also learn more about industry standards at the Water Jet Technology Association (WJTA).

What is CNC?

CNC, or Computer Numerical Control, automates machine tools using pre-programmed software. CNC machines follow precise instructions to cut, drill, or shape materials with minimal human intervention.

CNC Basics Explained

CNC systems interpret CAD designs, converting them into precise tool movements. This automation ensures consistent quality, reduces errors, and optimizes material usage.

Learn more about CNC fundamentals from Autodesk CNC Learning Resources.

Types of CNC Machines

CNC machines include milling machines, lathes, routers, and CNC water jets. Each type is tailored for specific materials and fabrication tasks.

See our guide on Pick a CNC Machine to Earn Money: Your Guide to Types, Uses, Prices, and Top Factories.

CNC in Water Jet Cutting

CNC technology enhances water jet cutting, enabling intricate shapes and designs impossible with manual methods.

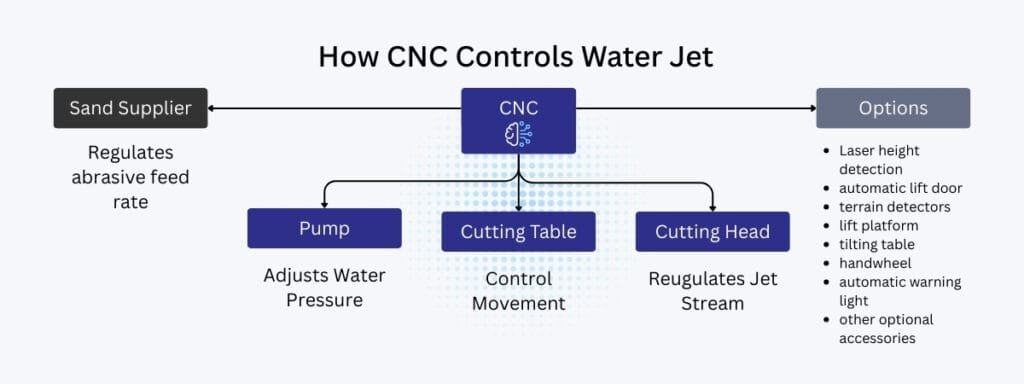

How CNC Controls Water Jet

| Component | CNC Control Method / Approach |

| Cutting Table | Moves along X, Y, Z axes with precise alignment and speed control |

| Pump | Adjusts water pressure dynamically based on material hardness and cut speed |

| Cutting Head | Controls nozzle angle, traverse speed, and kerf width for high-precision cuts |

| Sand Supplier | Regulates abrasive feed rate according to cutting speed and material type |

| Options | Laser height detection, automatic lift doors, terrain detectors, lift platform, tilting table, handwheel, automatic warning lights, and other optional accessories |

For detailed parts and features, see Water Jet Cutter: Five Core Parts, Optional Features, and Advanced Table & Head Solutions or visit Flow Waterjet Technology.

Advantages of CNC Water Jet

- High Precision: Tolerances as low as 0.1 mm.

- Material Versatility: Metals, stone, glass, plastics, composites.

- Non-Thermal Process: No heat-affected zones, preserving material integrity.

- Reduced Waste: Accurate cuts minimize scrap material.

Learn more at Waterjet Cutting: The All-Round Cutting Technology of Non-Thermal Processing and read research on CNC Water Jet Studies.

Applications

CNC water jet cutting is applied across industries, from industrial manufacturing to custom design projects.

Sheet Metal Fabrication

Cuts sheet metal precisely for machinery, automotive components, and HVAC systems.

See Sheet Metal Cutting Tools: Ultimate Selection by Metal Type & Thickness.

Stone Cutting

Ideal for architectural and decorative stone work.

See our case study: How a Waterjet Machine Transformed My Stone Processing Business.

Tube Cutting

Accurate cutting of metal and composite tubes, maintaining wall thickness and contours.

Glass Cutting

Cuts glass shapes without chips or cracks.

Learn more: Water Jet Cutting Machine: The Key Force Reshaping the Landscape of the Glass Processing Industry.

Composite Material Cutting

Cuts layered/reinforced composites for aerospace, automotive, and industrial parts.

See Acrylic Plexiglass Cutter – Choosing the Right Tool for Precision and Quality.

3D Material Cutting

Enables cutting of 3D surfaces and complex contours, ideal for molds and custom components.

See Tiles Cut Machine: Price, Types, and Best Tools Compare.

Real-World Results / Case Example

- A manufacturing plant reduced metal cutting time by 30% using CNC water jet technology.

- ROI was achieved within 6 months, thanks to increased efficiency and reduced material waste.

- Accuracy improved to ±0.1 mm, allowing high-tolerance components without secondary finishing.

Learn more about industry case studies from Flow Waterjet Technology.

Take Action

Ready to improve your fabrication process with CNC Water Jet Cutting? Contact our experts today to:

- Get a personalized quote

- Identify the best CNC water jet machine for your materials

- Explore optional features and advanced accessories