Can a Water Jet Really Cut Acrylic?

Yes — and it’s one of the most effective ways to cut acrylic cleanly and accurately.

Water jet acrylic cutting uses a narrow stream of water pressurized up to 60,000 psi or more to slice through acrylic sheets. Depending on the thickness and hardness of the material, a fine abrasive (like garnet sand) may be added to the jet to boost cutting power.

Unlike laser cutting or sawing, which rely on heat and friction, water jet cutting is a cold process. That means no melting, no burns, and no risk of cracking — just a smooth, clear finish.

How Water Jet Acrylic Cutting Works

Here’s a simplified breakdown of how the process operates:

- High-Pressure Generation:

The water is pressurized by an intensifier pump to create an ultra-fine jet capable of cutting through solid materials.

- Jet Formation:

The water passes through a precision sapphire or diamond orifice, forming a high-speed jet (0.1–0.3 mm wide).

- Optional Abrasive Addition:

For thicker acrylic, an abrasive such as 80-mesh garnet is added to improve cutting efficiency.

- CNC Path Control:

A computer-guided cutting head follows a programmed path, ensuring highly accurate shapes and smooth curves.

This process ensures no heat-affected zones (HAZ) and no material distortion, maintaining optical clarity and dimensional precision.

Why Choose Water Jet Cutting for Acrylic

Here’s why water jet acrylic cutting is often preferred over traditional methods:

- No Heat Damage

Acrylic cut by laser often turns white or frosty along the edges.

Water jet cutting eliminates this by using cold water — so edges remain perfectly transparent.

- Smooth, Polished Finish

The cut edges are clean and glossy straight off the machine. No need for flame polishing or secondary finishing.

- Compatible with Any Thickness

From 2 mm signs to 50 mm acrylic blocks, water jets maintain consistent precision.

- Eco-Friendly Process

No fumes, no melting, and no toxic residues. The process uses water and garnet, both recyclable and non-toxic.

- High Design Flexibility

The CNC system allows for complex contours, holes, and curves—ideal for customized products and artistic projects.

Common Applications of Water Jet Acrylic Cutting

Water jet acrylic is used across a variety of industries and design applications, including:

- Advertising & Signage: Letters, logos, lightbox panels

- Architecture: Transparent panels, partitions, and furniture accents

- Industrial Components: Covers, guards, inspection windows

- Art & Design: Sculptures, display models, and creative prototypes

Its precision, clarity, and versatility make it a top choice for both mass production and one-off designs.

Water Jet vs Laser Cutting for Acrylic

| Feature | Water Jet Acrylic | Laser Cutting |

| Cutting Type | Cold, high-pressure water | Hot laser beam |

| Edge Quality | Smooth and transparent | May melt or frost |

| Material Thickness | 1–50 mm | Usually ≤15 mm |

| Heat Damage | None | Possible |

| Fumes & Residue | None | Smoke and dust possible |

| Post-Processing | Not needed | Often required |

💡 Verdict: When precision and clarity matter, water jet acrylic cutting is the superior choice.

Expert Insight: Why Manufacturers Prefer Water Jet Acrylic

Professionals in sign-making, lighting, and display fabrication often choose water jet systems for acrylic because:

- The process preserves material transparency, saving post-processing time.

- It supports batch production with repeatable accuracy.

- Maintenance and operation costs are lower over time compared to laser cutting for thick materials.

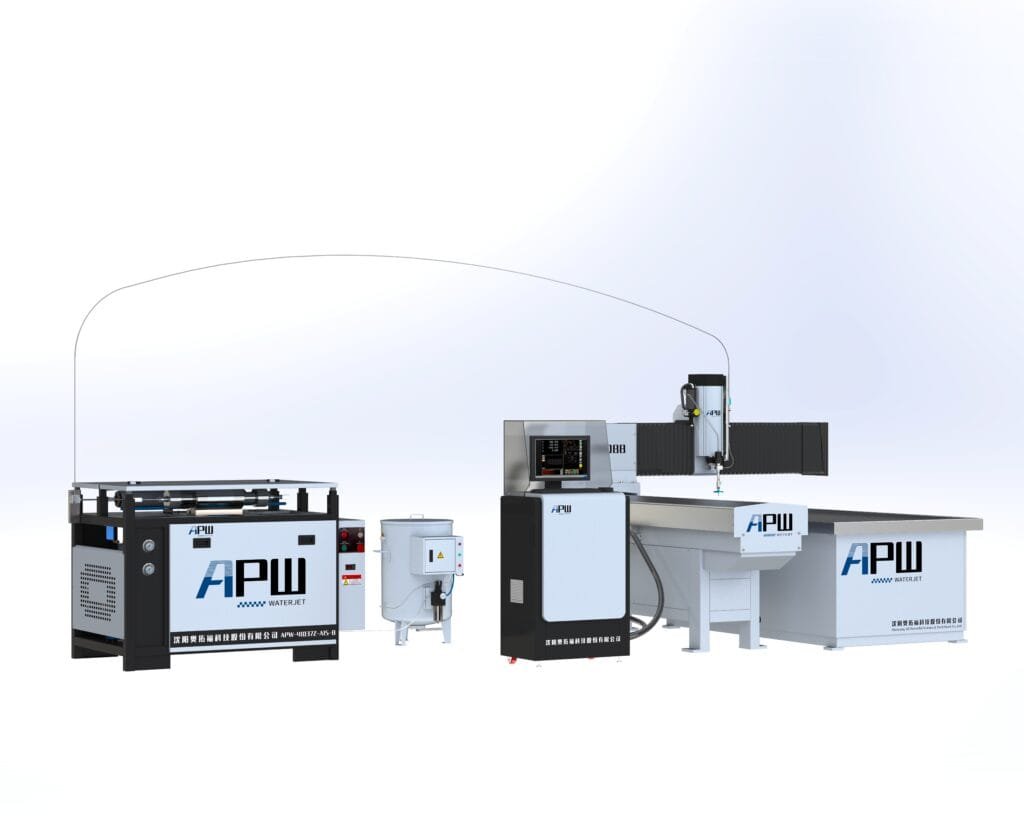

- Recommended Model: For workshops with limited space or requiring flexible operation, the APW-2010BB cantilever water jet is an excellent option.

Its small-room footprint and three-sided open platform allow fast material uploading and unloading — perfect for acrylic, metal, and composite cutting in compact environments.

The cantilever structure provides easy operator access, ensuring both productivity and comfort.

Trusted manufacturers like APW Waterjet continue to refine small and large-format systems that deliver industrial precision, long-term stability, and global service support.

So, can you cut acrylic with a water jet?

Absolutely — and it’s often the best way to achieve flawless results.

Water jet acrylic cutting delivers cold, clean, and accurate cuts across all thicknesses.

It keeps your material crystal-clear, your workshop air clean, and your production efficient.

If your project values clarity, sustainability, and precision, a water jet cutter is the tool that meets every need.

FAQs About Water Jet Acrylic Cutting

Q1: Does water jet cutting crack acrylic?

No. Because it’s a cold-cutting process, there’s no thermal stress. Properly supported acrylic won’t crack or chip during cutting.

Q2: How thick of an acrylic sheet can a water jet cut?

Most industrial machines can cut up to 50 mm (2 inches) of acrylic, depending on the system’s pressure and nozzle type.

Q3: Is water jet cutting better than laser for thick acrylic?

Yes. Laser cutting struggles with thick acrylic because of heat buildup. Water jet cutting handles it easily with no burn marks.

Q4: Can I achieve polished edges with a water jet?

Yes — the edges come out smooth and glossy, often requiring no further polishing.

Q5: Is water jet acrylic cutting environmentally friendly?

Definitely. It uses water and garnet abrasive, both of which are recyclable and non-toxic.

Q6: Which water jet machine is suitable for small workshops?

For compact environments or flexible operation, the APW-2010BB cantilever water jet offers an ideal balance of size, accessibility, and cutting precision.

Learn more : Contact Sales ; Watch acrylic cutting viedos

Explore APW water jet systems engineered for precision cutting of acrylic, glass, metal, stone, and composite materials.