Best Sell

APW-3020BA-A15-B-BP

> Table Size: 3m(X axis)*2m(Y axis)

> Pump Power: 37KW, 3.7L/min HP Flow

> Cutting Head: 3 Axis, 150mm Z-travel, 0.33 Nozzle, Pure water or abrasive swifts flex

Application: most cutting industries

Customer industries: glass processing / refractory materials cutting / rubber cutting / sandpaper cutting

Choose Reason: Classical, Value for money, Freshman friendly

Details of Best Sell Water jet Cutter

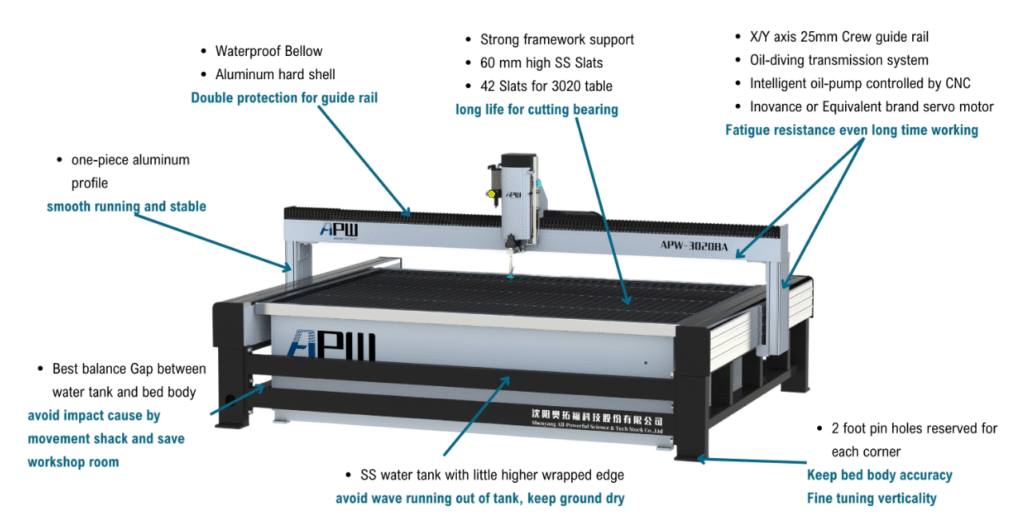

Table

- suit for most of raw materials

- 3m(X axis)*2m(Y axis)

- Cutting Accuracy: 0.1mm

- Repeatability: 0.03mm

- Traverse Speed: 10m/min

- Load Capacity: 500KG/㎡

- Bridge like axis runway and Separate frame and water tank keep stability and reduce the impact on cutting accuracy

- 2 sides uploading

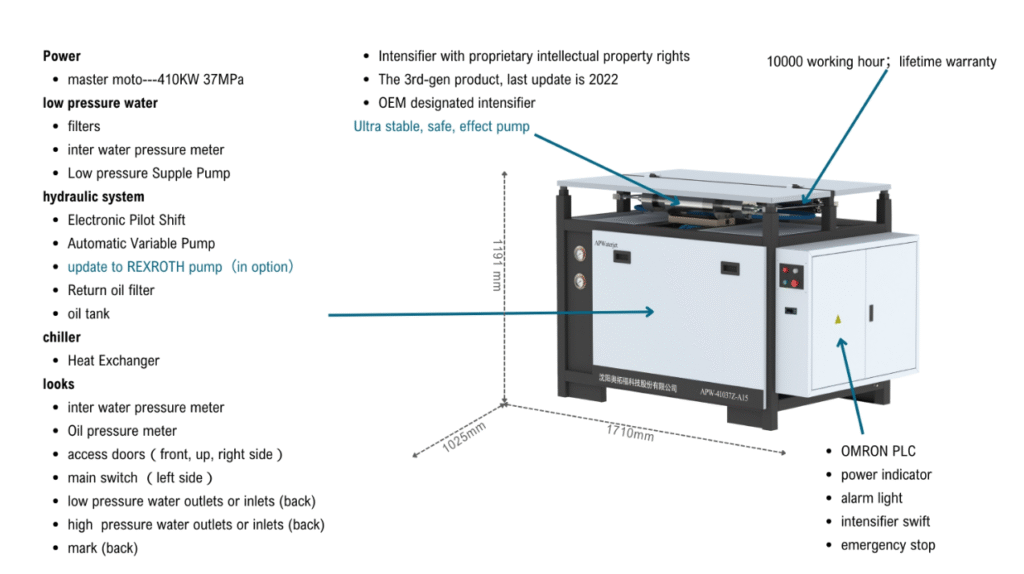

Pump

- Power Rate: 37KW

- Electricity Supply: AC380V 50HZ 3PH

- Max.Pressure: 420MPa

- HP Water Flow Rate: 3.7L/min

- 0.33mm nozzle(jet diameter)

- Accumulator: 1.2L

- Oil Tank: 114L

- Size: 1710*1025*1191mm

- Weight: 980KG

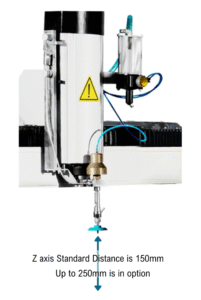

Head

- 3 axis head

- 150mm Z-travel

- pure water or abrasive swifts flex

Friendly

- Fresh man friendly

- easy operation, easy maintenance

Feedback

- Mature technology is capable of handling the vast majority of tasks

- Nearly no complaint

- Best market feedback

Cost

- 5 Parts of equitment combo are all functional

- Best-selling means that as a mass-produced product, it has a fair price, and its accessories and consumables are easy to purchase at reasonable prices.

- Being the most classic product means that the return on investment is very substantia

| Structure Type | Bridge Style |

| Way of Drive | AC Servo |

| Power Supply | AC 220V, 50Hz/60Hz |

| Total Power | <6.79HP / 5KW |

| Load Capacity | 500KG/m2 |

| Control Accuracy | ±0.01mm |

| Positioning Accuracy | ±0.04mm/1000mm |

| Repeatable Positioning Accuracy | ±0.05mm |

| Cutting Speed | <3m/min |

| X axis Max. Moving Speed | 10m/min |

| Y axis Max. Moving Speed | 10m/min |

| Z axis Max. Moving Speed | 1m/min |

| Table Material | Stainless steel |

| Thickness | 3mm |

| More Table Sizes Available | |||

| Bridge-BA | X Axis Travel mm | Y Axis Travel mm | Z Axis Travel mm |

| 2015BA | 2000 | 1500 | 150 |

| 2515BA | 2500 | 1500 | 150 |

| 2030BA | 2000 | 3000 | 150 |

| 3015BA | 3000 | 1500 | 150 |

| 3020BA | 3000 | 2000 | 150 |

| 2040BA | 2000 | 4000 | 150 |

| 4020BA | 4000 | 2000 | 150 |

| etc | etc | etc | etc |

pump

| General | |

| Main Motor Power | 50HP/37KW |

| Max. Working Pressure | 420Mpa/60000PSI |

| Continuous Working Pressure | 360-380Mpa |

| Max. Water Discharge | 3.7L/min |

| Max. Orifice Available | 0.33mm |

| Power Supply | 380V/50Hz/3PH |

| Noise Level | 75db(A) |

| Size | 1710*1025*1191mm |

| Weight | 980KG |

| Cutting Water System | |

| Min. Inlet Cutting water | 16L/min |

| Min. Inlet Cutting Water Pressure | 0.24Mpa |

| Accumulator Volume | 1.2L |

| Hydraulic System | |

| Max. Hydraulic Pressure | 20Mpa/2900PSI |

| Oil Tank Capacity | 114L |

| Cooling System | |

| Min. Inlet Cooling Water | 12L/min |

| Min. Inlet Cooling Water Pressure | 0.3Mpa |

head

| Type | 3-axis |

| Z axis Travel | 150mm |

| A axis tile angle | 0 |

| B axis tile angle | 0 |

| C axis tile angle | 0 |

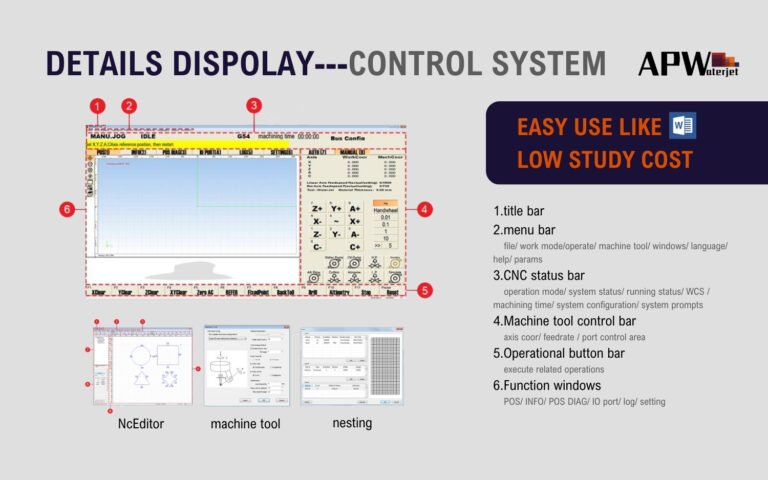

control system

| Name | NC-Studio |

| Features | |

| Easy use | |

| Low study cost | |

| Multiple O-Point settings | |

| Built-in CAM, NCEditor | wear-and tear part management |

| Supports multiple process settings | bridging/micro-linking/chamfering/ beveling/sorting/ vertical |

| supports the linkage of various auxiliary functions | laser height detection, edge-finding, barcode scanner reading, drill bit lifter |

| ceramic sink cutting treatment | visual contour extraction |

| machine tool management | |

| nesting |

| Main windows | |

| Title bar | |

| Menu bar | file/workmode/operate/machine tool/windows/language/help/params |

| CNC status bar | operation mode/ system status/ running status/WCS/ machining time/ system configuration/ system propts |

| Machine tool control bar | axis coor/ feedrate/ pot control area |

| Operational button bar | execute related operations |

| Function windows | POS/INFO/POS DIAG/ IO port/log/setting |

auto abrasive delivery system

| General | |

| Max. Inlet Air Pressure | 0.8Mpa |

| Min. Inlet Air Pressure | 0.2Mpa |

| Abrasive Capacity | 270Kg |

| Operating Air Flow | 0.5 m3/min |

| Volume | 590x590x1340mm |

| Power Supply | GC24V |

| Features |

| Self-feeding Control |

| Self sealing |

| Air Valve to prevent jams and breakages |

| Use non-metallic sensor to work acutely and long work life |

No.1

The biggest water jet factory of china , 300 sets of water jet per year

Full Production Chain

design-machining-assembly-QC-warehousing-sale-technical support

1800+ Fans

5000+ Water jet Cutters for 1800+Customers in 60+ Countries

No-Stop Forward

Optimization, new types and new patents for water jet every year

best sell water jet FAQ

1. Why is the 3020BA-15-B-BP considered a best sell water jet?

It combines high precision, stable performance, and versatility, making it ideal for multiple industries.

2. What materials can this best sell water jet cut?

This best sell water jet can handle stone, glass, metal, composites, and more, ensuring clean and precise cuts.

3. Is the 3020BA-15-B-BP suitable for both factory and workshop use?

Yes, this best sell water jet is designed for flexibility, suitable for both industrial factories and smaller workshops.

4. How does this best sell water jet improve production efficiency?

Its high-speed cutting, precise nozzle system, and robust pump enable faster, cleaner cuts, reducing waste and improving productivity.

5. What makes this APW water jet a top choice for customers?

The combination of reliability, ease of operation, competitive pricing, and comprehensive after-sales support makes it a best sell product worldwide.