Water Jet Knowledge: Basics of Water Jet Cutting

Water jet cutting is a modern, efficient, and precise cutting process widely used in industries worldwide. This water jet cutting technology employs a high-pressure stream of water, sometimes mixed with abrasives, to cut through a variety of materials. The advantages of water jet cutting include cold cutting characteristics (no heat-affected zone), high precision, and environmental friendliness, making it a core part of water jet knowledge for manufacturers in China and globally.

The basic principle of water jet cutting is straightforward: water is pressurized by a high-pressure water jet pump and travels through specially designed pipes and joints before being ejected at high speed from the cutting head nozzle. While the process is easy to operate, it involves advanced water jet knowledge in fluid dynamics, material science, and mechanical design.

Modern water jet pumps can achieve pressures ranging from 280–620 MPa. In a complete water jet cutting system, the pressurized water flows through ultra-high-pressure piping, including T-joints, elbows, swivels, and flexible stainless steel tubes, until it reaches the cutting head. A high-speed pneumatic on/off valve controls the water flow through a gemstone nozzle, creating a supersonic water jet.

As the water jet exits the nozzle, the high pressure is converted into velocity. The resulting supersonic water jet cutting stream can reach several hundred meters per second and easily cut through materials ranging from soft foams to hard metals, stones, and composites. Understanding these principles is fundamental water jet knowledge, especially for engineers and technicians working with water jet systems in China or abroad.

Low pressure water turns to high pressure waterjet by intensifiers as a core part of pump.

The sealing between components is the key to generating stable HP water.

There are many different fixing devices to carry nozzle, the whole called cutting head.

You can also use water jet cutter in outdoor site, not be limited in factory cell

Sand is not necessary for soft marterials

Methods and Technique

HP PURE WATERJET CAN CUT

Rubber, Foam, Plastic, Gasket, Paper, Clothes, Disposable Diapers, Food and so on.

Abrasive(sand) is must

Glass, Ceramic, Tile, Stone, Metal, Composite, multi-layers simple and so on

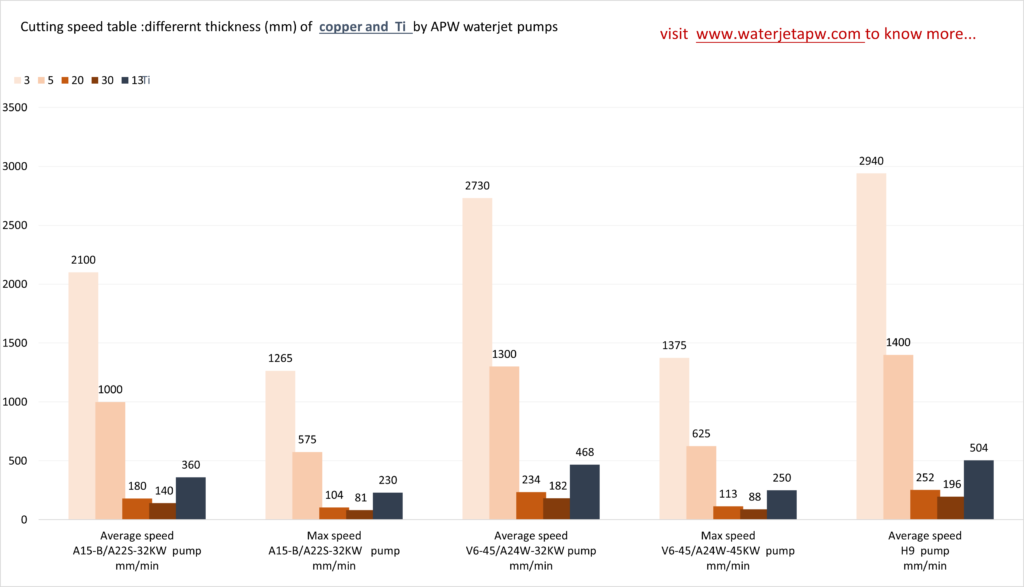

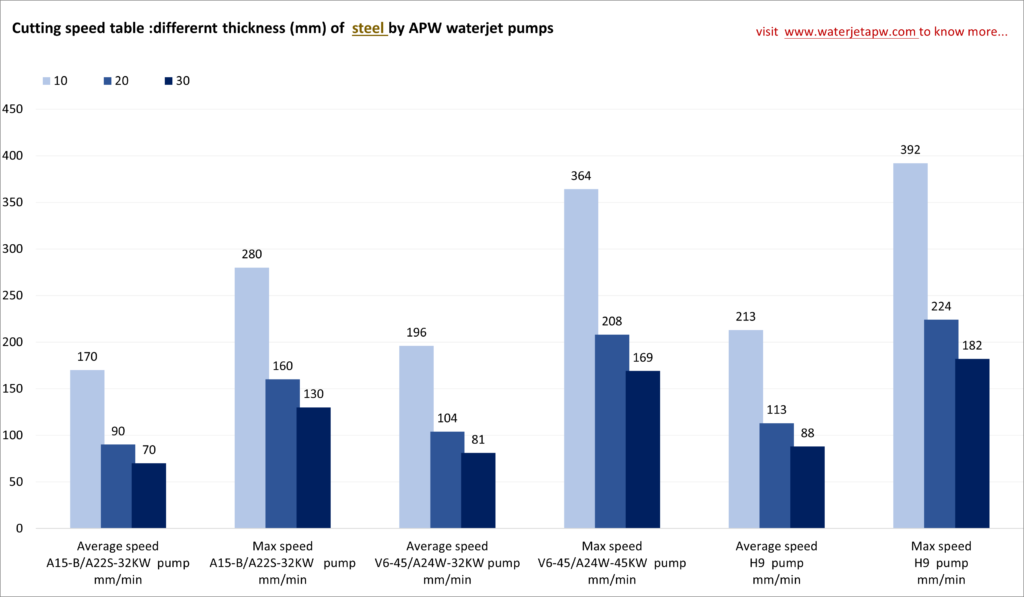

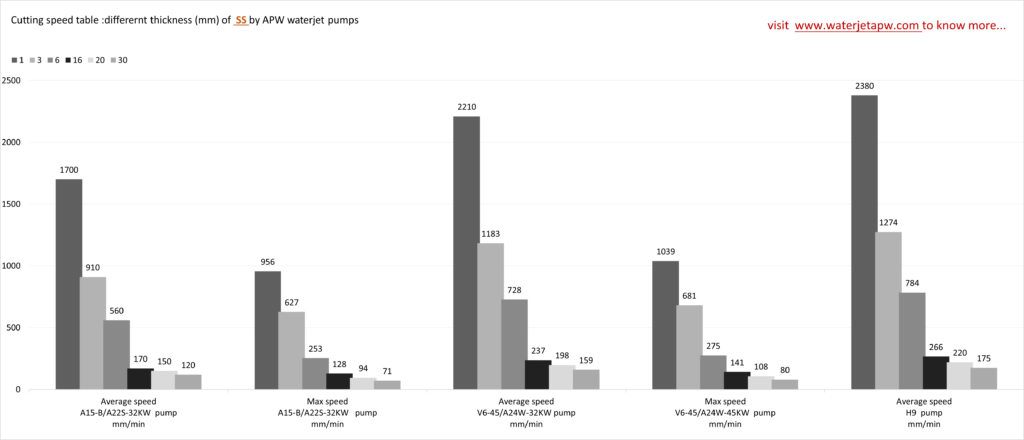

Evaluating Cutting Capabilities in 3 Key Aspects

- The thickness of materials that can be cut

- The cutting speed for the same material

- The edge smoothness under the same material and speed conditions

we test APW Pumps' cutting capability , hope it's useful to you

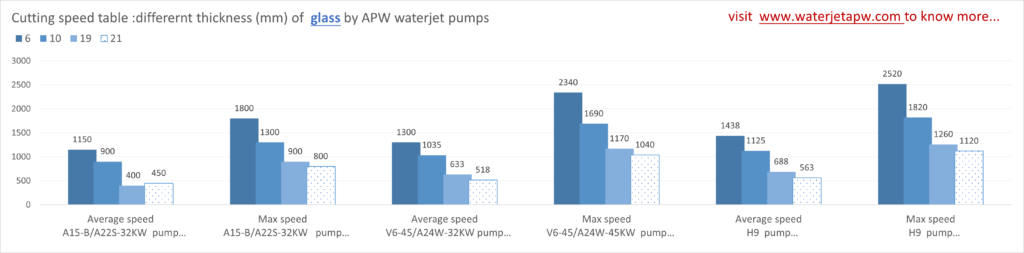

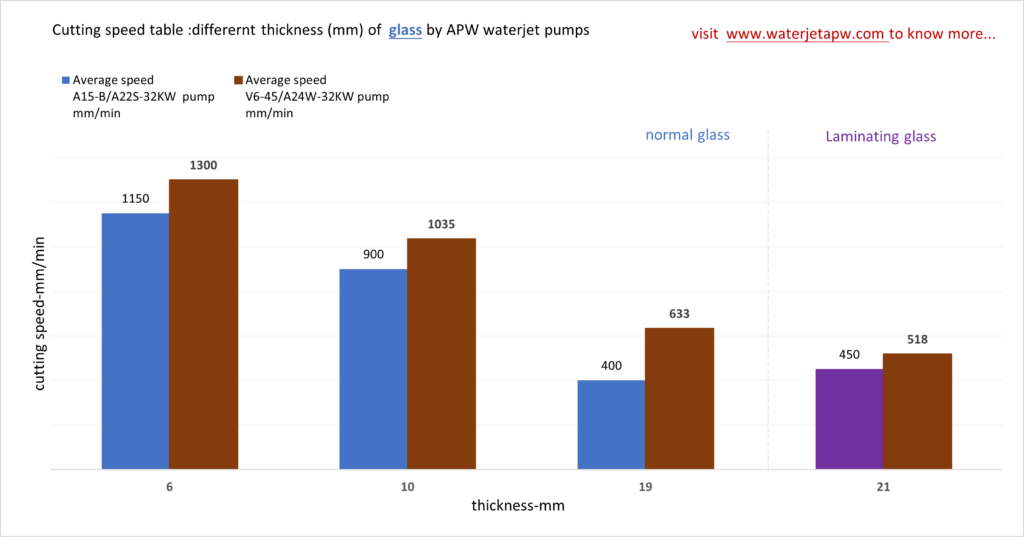

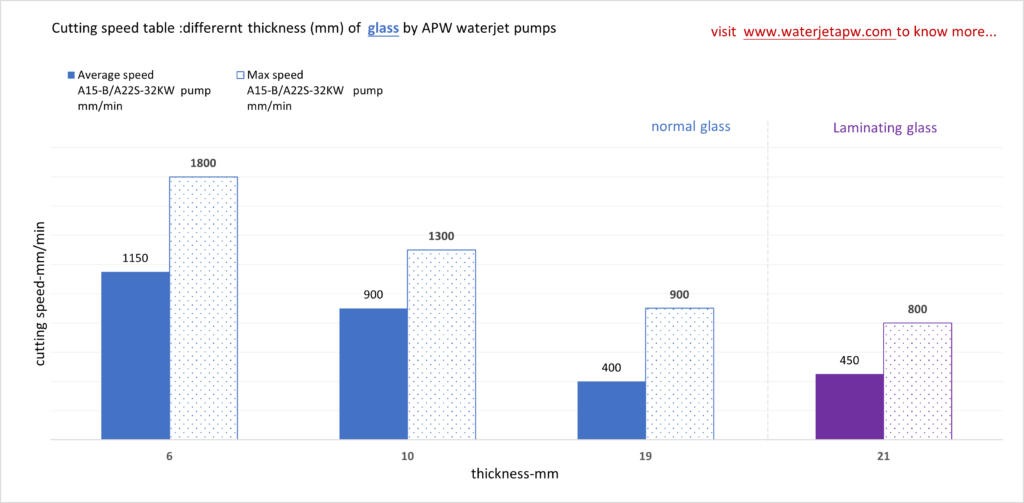

Water jet cut Glass Speed chart

normal glass, laminating glass

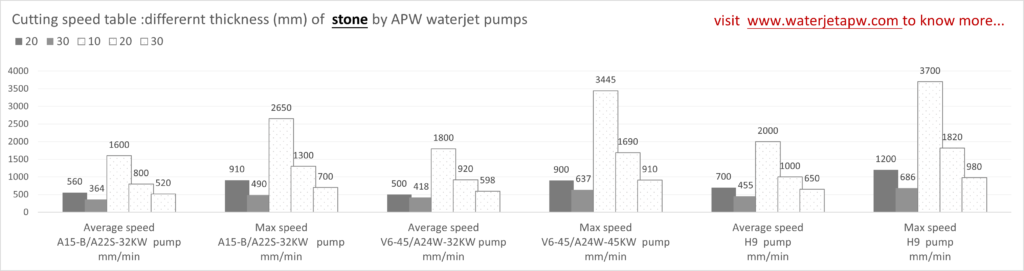

Water jet cut stone Speed chart

marble

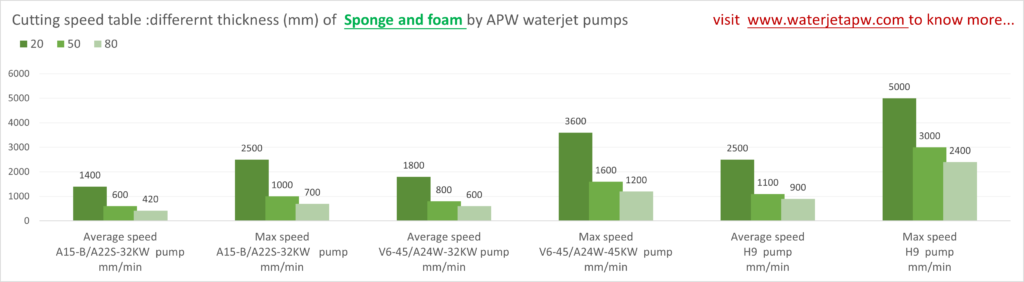

Water jet cut sponge and foam Speed chart

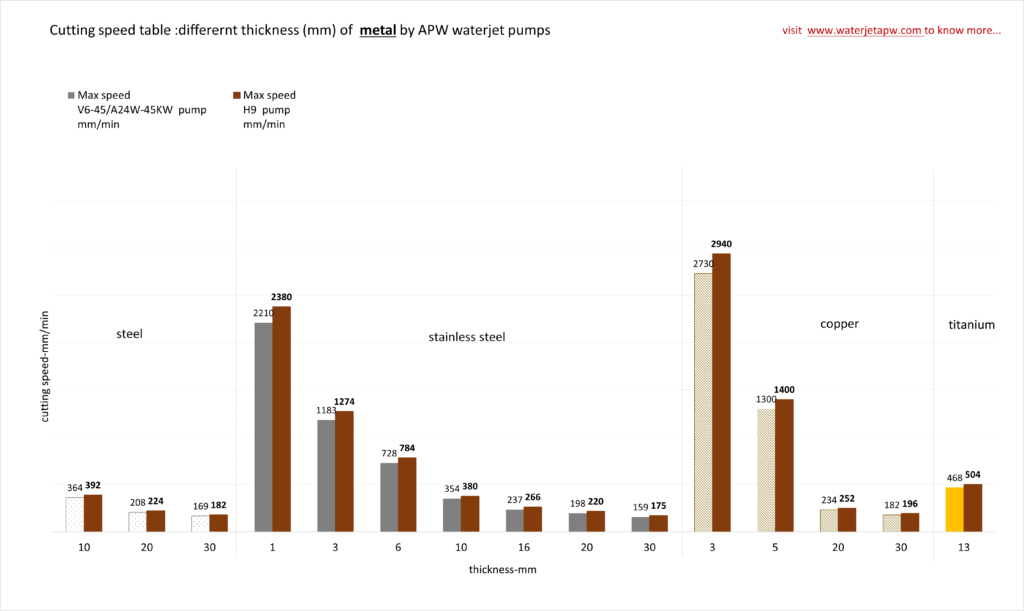

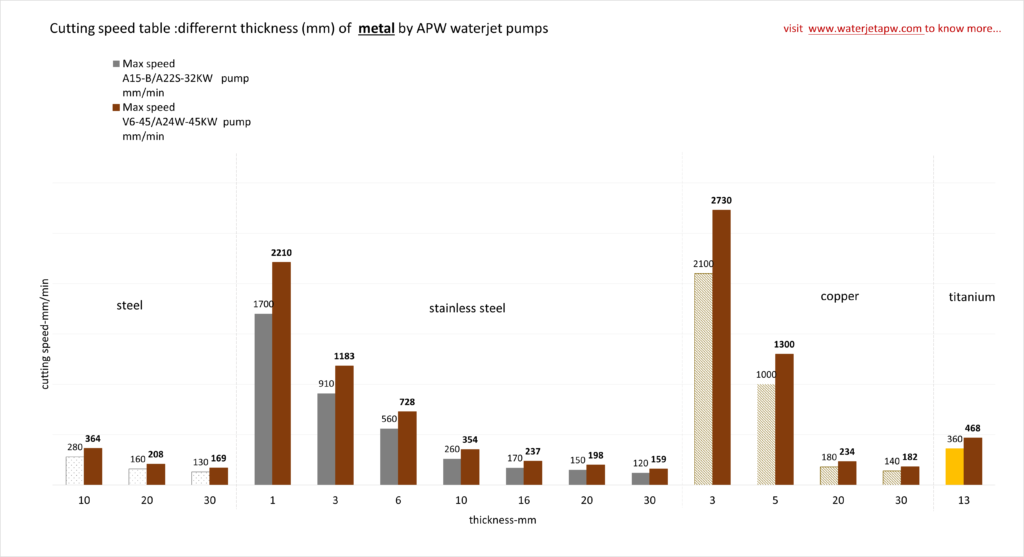

Water jet cut Metal Speed chart

steel. stainless steel, copper, titanium

Water jet knowledge encompasses a broad spectrum of technologies and applications crucial in modern manufacturing and material processing. At its core, a water jet is a high-pressure stream of water used in water jet cutting to slice through various materials with precision and versatility. Mastering water jet knowledge is essential for engineers and technicians working with water jet systems in China or globally.

Water jet cutting operates on the principle of converting hydraulic pressure into kinetic energy. High-pressure water jet pumps force water through a tiny orifice, creating a focused stream that easily cuts soft materials like rubber and foam. For harder materials such as metal, glass, and stone, abrasive particles like garnet are added to the water stream. This abrasive water jet cutting technology significantly enhances cutting power, enabling precise slicing of thick plates and intricate designs.

One of the key advantages of water jet cutting is its cold-cutting nature. Unlike laser or plasma cutting, water jets generate minimal heat, preventing thermal distortion and ensuring high-quality finishes and dimensional accuracy. This makes water jet cutting ideal for heat-sensitive materials and complex shapes, reducing tooling costs and increasing production flexibility.

Water jet knowledge is also crucial for understanding industrial applications. In the aerospace sector, water jet cutting is used for lightweight composites and precision components. The automotive industry relies on water jet cutters for accurate metal part fabrication, while the food industry benefits from hygienic and precise water jet cutting for products like meats and fruits. Overall, strong water jet knowledge ensures efficient, accurate, and cost-effective cutting solutions for a wide range of materials and industries, both in China and worldwide.

water jet cutting videos

watching how does cutter work