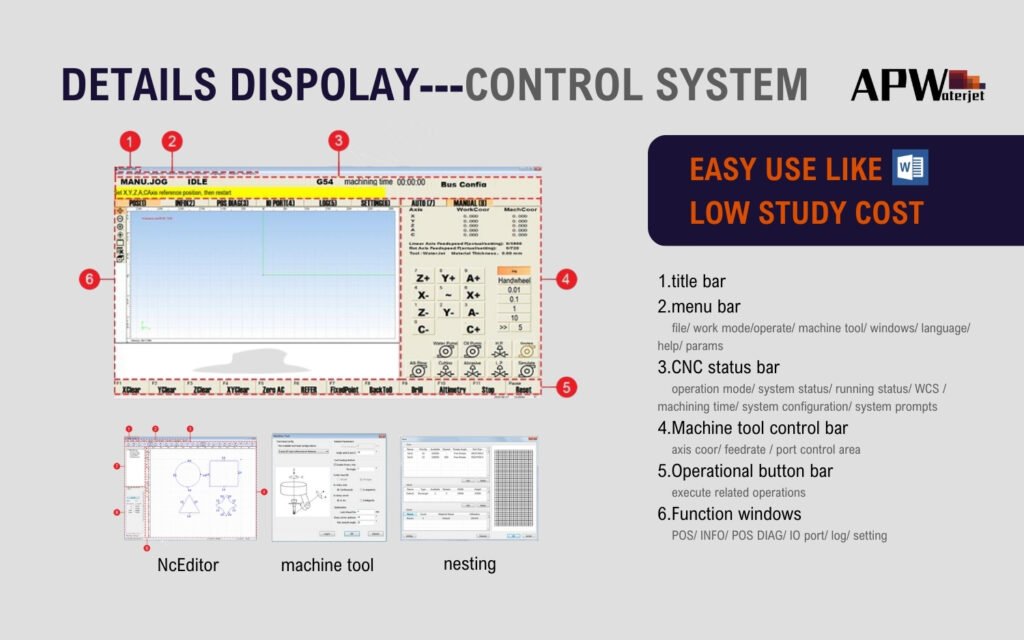

APW carefully selects the most stable and easiest CNC control system on the market. Its functions are both simple and comprehensive, ensuring the lowest learning curve. Whether you are a beginner or an experienced operator, you can quickly master it for efficient and precise water jet cutting. With outstanding reputation and user feedback, the APW system has become the most favored choice in the industry.

Moreover, the system seamlessly integrates with APW’s entire product line, perfectly matching all water jet machine models, enhancing overall equipment performance and user experience, helping customers achieve production goals swiftly.

APW NC Studio CNC Control System — Stable, Simple, Fully Integrated Across APW Water Jet Machines

Core Features

1. Powerful Parsing Functions (Bevel Cutting and Taper Cutting for Sheet Materials)

Bevel Cutting for Sheet Materials

The system automatically converts imported 2D drawings into 5-axis 3D cutting data, enabling fast and easy cutting of simple bevel surfaces, significantly improving machining efficiency and accuracy.

Arc Taper Cutting

Users can customize the material radius parameter, and the system automatically generates cutting paths on arc surfaces, enabling complex taper cutting to meet the high-precision machining needs of irregular workpieces.

2. Built-in Optional Functions (No Additional Development Needed)

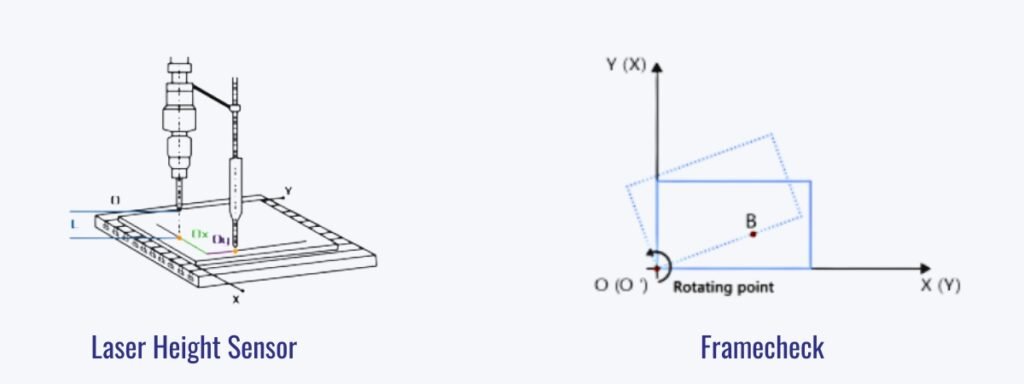

Automatic Height Measurement

Using laser recognition technology, it effectively addresses uneven material surfaces, ensuring stable cutting quality. Supports three measurement modes: manual measurement, planar three-point measurement, and real-time dynamic measurement during cutting, maintaining optimal nozzle-to-workpiece distance to enhance cutting performance and nozzle lifespan.

Frame Check

Designed to solve the difficulty of adjusting large or heavy materials placed at an angle, it offers both automatic and manual detection modes. Supports single-point, double-point, and three-point edge detection, automatically recognizing workpiece position and angle, assisting in precise alignment and improving accuracy and repeatability.

Combination of Drill Bit and Water Jet Cutting

Addresses the low piercing efficiency of water jets and poor multi-layer material piercing. Supports drilling only circular holes, drilling single holes before cutting, or drilling multiple holes before overall cutting, significantly improving efficiency and quality for thick and multi-layer materials.

Consumable and Working Time Management

The system monitors usage time of consumables such as nozzles and mixing tubes in real time, automatically reminding for maintenance and replacement, preventing downtime caused by worn parts.

Meanwhile, the working time management module records cumulative running hours of the high-pressure pump, helping users calculate labor hours, power consumption, and other production management tasks, improving operational efficiency.

3. Professional Technic Library (Flexible Process Adjustment and 5-Axis Cutting Support)

Clear, simple interface supports flexible start/end switch timing. Multiple drilling methods with simple speed parameters ensure maximum efficiency. 5-axis cutting offers fixed bevel and dynamic 5-axis modes for complex, high-precision parts.

4. User-Defined PLC Time Sequence (Comprehensive Timing Editing)

Supports editing valve switch actions, M-code control, and process node timing logic. Freely configures I/O input/output ports, analog outputs, PWM pulse outputs, delay times, and independent G-codes for personalized control.

5. Flexible IO Port Assignment (Highly Customizable)

Technicians freely assign IO port functions, customizing control logic per habits. Simple, user-friendly interface supports flexible expansion.

Advantages of APW NC Studio

- Most Stable and Reliable: Ensures continuous efficient operation and reduces downtime.

- Simple and Easy to Learn: Lowest learning curve for quick mastery and productivity boost.

- Rich and Comprehensive Features: Meets diverse and complex machining needs with high quality.

- Seamless Integration with APW Product Line: Perfect compatibility with all APW water jet models, enhancing overall performance and user experience.

- Smart Consumable Management: Extends component life and minimizes maintenance downtime.

Application Areas

- Metals (stainless steel, aluminum, titanium alloys, etc.)

- Stone (granite, marble, etc.)

- Glass (architectural, automotive, etc.)

- Composites (carbon fiber, laminated panels, etc.)

With its outstanding stability, ease of use, and rich features, the APW NC Studio CNC control system perfectly integrates with APW’s entire water jet product line, making it the ideal choice for enterprises seeking efficient and high-quality machining.