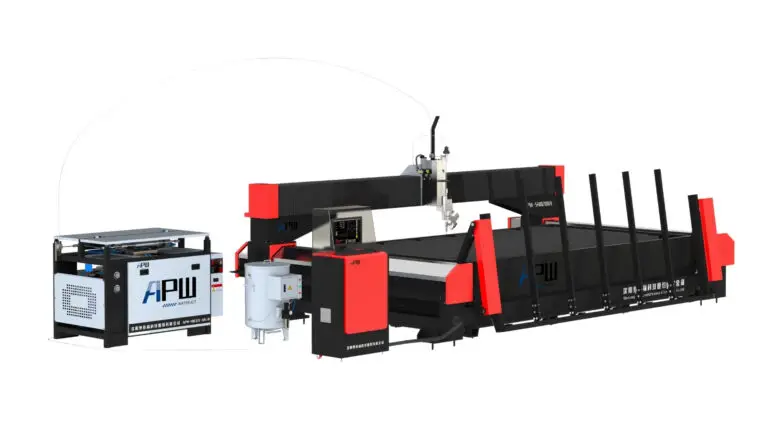

Waterjet Cutter

Advanced Combo Cutting Solution

APW waterjet cutter series provides high precision and flexibility for industries including metal, stone, glass, and composite cutting. This advanced waterjet cutter combo machine integrates efficiency with durability, helping manufacturers reduce costs while maintaining cutting accuracy.

Saving Power Pump

Servo motor

More Powerful Pump

high power motor

functional tables

Meet industry needs

diverse heads

3D/ Batch Cutting

Saving Power Pump

Servo motor

Advantages and highlights

The AX series high-pressure pump is a representative product in the medium power range, designed for users with high requirements for performance and stability. It uses plunger pumps from internationally renowned brands (such as Rexroth) and has an automatic adjustment function, which can accurately control pressure and flow according to cutting requirements.

The AX series pump has a stable output flow and small pressure fluctuations, ensuring high precision and high efficiency in the cutting process. In addition, its compact design and optimized structure make it perform well in the medium power range and suitable for a variety of complex processing tasks.

Model

- A22S-24 (23.9KW)

- A22S-32 (32.8KW)

- A22S-37 (38.8KW)

- A24W-45 (45KW)

- A24W-75 (75KW)

Applicable scenarios

It is suitable for medium-sized processing enterprises, especially in the fields of metal processing, stone cutting, etc. that have high requirements on cutting accuracy and efficiency

technical parameter

- Power(KW): 23.9/32.8/38.8/45/75

- Plunger Pump brand: Rexroth

- Plunger Pumps count: 1

- Intensifiers count: 1(S) / 2(W)

- HP Water flow(L/min): 3.7(S) / 7.4(W)

- nozzle(mm): 0.26/0.3/0.33/0.46

- HP Water Max Pressure(MPa): 360/380/413

- Control Display: have(S) / none(W)

- Size(mm): 1715*1045*1272 (S) / 2100*1370*1510(W)

- Weight(KG): 1100 / 1400 / 1700

Powerful Pump

High Power motor

Advantages and highlights

The V series high-pressure pump is APW ‘s high-end product, designed for high-intensity processing needs. Its power range is from medium-high power to ultra-high power, and it can provide strong pressure and flow support. The V series pump uses advanced boosting technology and high-performance plunger pumps. Some models are equipped with dual plunger pumps, which further improves output capacity and stability. Its automatic adjustment function

and high-precision control ensure the efficiency and consistency of the cutting process, making it an ideal choice for difficult processing tasks.

Model

- V6-45 (45KW)

- V6-55 (55KW)

- V6W-75 (75KW)

- V6W-94 (94KW)

- V6W-112 (112KW)

Applicable scenarios

It is suitable for large-scale processing enterprises, aerospace parts manufacturing, heavy machinery processing and other fields, and can meet the cutting needs of high pressure and large flow.

technical parameter

- Power(KW): 45/55/75/94/112

- Plunger Pump brand: Chinese/Rexroth

- Plunger Pumps count: 1(45/55) / 2(75/94/112)

- Intensifiers count: 1(45/55) / 2(75/94/112)

- HP Water flow(L/min): 6(45/55) / 12(75/94/112)

- nozzle(mm): 0.36/0.4/0.46/0.52/0.57

- HP Water Max Pressure(MPa): 413

- Control Display: have(S) / none(W)

- Size(mm): 2265*1552*1530 (45/55/75) / 2250*1400*1370(94) / 2050*1400*1400(112)

- Weight(KG): 1300 / 1600 / 1700 / 2600 / 3200

What would you do to upgrade the classic combo for the first time? If it is the golden age of youth and energy, increasing functionality or convenience is the first choice, but in the era of economic contraction, reducing energy bills is the best choice.

Just a small change can bring at least 30% cash flow expenditure. If you punch more holes, the profit will be even greater.

Size available (X*Y) (mm)

2000*1500; 3000*2000; 2000*4000; 3000*4000; 2000*6000; 3000*5000; 3000*6000

- Structure Style: Bridge style

- Control System: NC Studio

- Power Supply: 3PH,AC380V,50HZ

- Nominal Power: 5KW

- Max. Loading Capacity: 500KG/㎡

- Drive Way: Ball Screw

- Table Size(X-Y): 3000mm*2000mm

- Z-Travel: 150m

- Head: 3 axis

- Cutting Accuracy: ±0.1mm

- Max.Travel Moving Speed: 10m/min

- Working Temperature: 5-40℃

Want to get more out of this? If you cut multiple small shapes from a board, the AX series pump combined with a faster-moving cutting head is a great choice.

Size available (X*Y) (mm)

3000*2000; 2000*4000; 2000*6000; 2000*8000; 2000*12000; 2000*14000

- Structure Style: Bridge style

- Control System: NC Studio

- Power Supply: 3PH,AC380V,50HZ

- Nominal Power: 5KW

- Max. Loading Capacity: 500KG/㎡

- Drive Way: Rack and Pinion

- Table Size(X-Y): 3000mm*2000mm

- Z-Travel: 150m

- Head: 3 axis

- Cutting Accuracy: ±0.1mm

- Max.Travel Moving Speed: 30m/min

- Working Temperature: 5-40℃

APW-A22S-GJ1010-DXACWZ

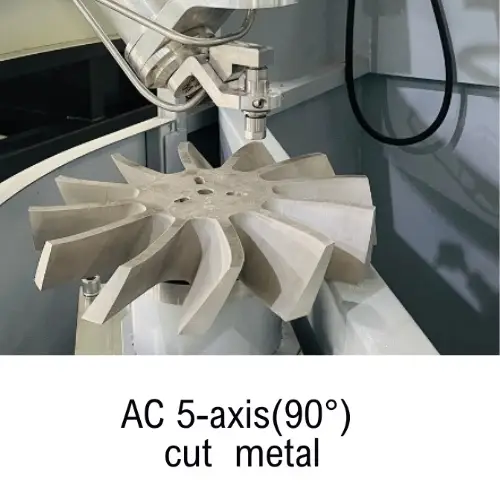

If you are a laboratory or small studio, you face a variety of requirements and do not have sufficient labor, space and budget like a factory. This GJ table can meet almost all your needs:

3D cutting + energy saving + small size + environmentally friendly + safety protection + drawer-type water tank is easy to clean.

Size available (X*Y) (mm)

500*500; 800*800; 1000*1000; 1200*1200

- Structure Style: Fully Protection

- Control System: NC Studio

- Power Supply: 3PH,AC380V,50HZ

- Nominal Power: 5KW

- Max. Loading Capacity: 500KG/㎡

- Drive Way: Ball Screw

- Table Size(X-Y): 1000mm*1000mm

- Z-Travel: 150m

- Head: AC 5 axis

- Cutting Accuracy: ±0.1mm

- Max.Travel Moving Speed: 10m/min

- Working Temperature: 5-40℃

functional tables--- Meet industry needs

APW-A15+B-G2060-ACWZ

It is suitable for cutting tasks with complex three-dimensional shapes, such as large sculptures, complex curved metal parts, etc., providing a reliable solution for difficult processing

The high-frame series waterjet cutter is designed for three-dimensional cutting of irregular shapes and high-size materials. Its double-sided gantry support mechanism adopts one- piece frame welding, and the support frame height can be infinitely expanded according to user needs, so as to achieve high-stroke cutting needs. High-standard heat treatment process and aging treatment ensure the overall accuracy and stability of the equipment. The bridge gantry structure and double guide rail design of the spindle further improve the operating accuracy of the actuator. In addition, the Z-axis adopts high-performance servo motor drive and

double guide rail structure design to ensure the stable operation of the five-axis cutter head and three-axis cutter head.

Size available (X*Y) (mm)

3000*2000; 2000*4000; 2000*6000; 3000*6000

It is particularly suitable for heavy-duty material cutting that requires high-rigidity support and high-precision processing, such as large stone processing, thick metal plate cutting, etc., and can meet users’ needs for high-strength and high-precision processing

The enhanced series waterjet cutter is designed for processing large stone, rock and metal plates, with extremely high rigidity and stability. Its heavy-duty high-quality pipe welding body is annealed to high standards and is not easily deformed after long-term use. The spindle adopts a unique bridge gantry structure and a double-guide rail running design, which further improves the running accuracy of the actuator. The water tank is made of thick metal plates, and the grille adopts a grid structure, which is processed and formed in one go to ensure overall flatness and durability.

Size available (X*Y) (mm)

3000*2000; 2000*4000

APW-V6-G3020-18-DXACWZ

It is suitable for places with high requirements on the working environment, such as precision electronic component processing, medical equipment manufacturing, etc. It can effectively improve production efficiency while ensuring employee health and equipment safety.

The fully enclosed series waterjet cutter is the first fully enclosed machine-type waterjet cutting machine developed in the industry, with special attention paid to the on-site working environment and the occupational health and safety of employees. Its fully enclosed workbench design can effectively avoid sand and water splashing during cutting, reducing the impact on the working environment. The suspended integrated control console saves space and is easy to operate. The electric/pneumatic automatic lifting door has a safety interlocking function, which is convenient for loading and unloading, and is equipped with an observation window for operators to monitor the cutting process in real time. The split structure design effectively avoids the impact of water flow on the bed during operation, further improving the stability and service life of the equipment.

Size available (X*Y) (mm)

3000*2000; 2000*4000; 3000*4000; 2000*6000; 2000*8000; 2000*10000; 2000*12000

APW-A22S-LX-3020BA-BP-ZZ

It is suitable for large-scale automated production lines, such as glass processing, ceramic product production, etc. It can achieve efficient and stable automated cutting, reduce labor costs and improve production efficiency

The Link Series waterjet cutter is an innovative product of APW that deeply integrates waterjet cutting technology with automated production lines. Its open signal interface can seamlessly connect to the mainstream MES system to realize data reading, signal transmission and automated control tasks, truly realizing unmanned operation. It is equipped with dual cutting heads and dual sand supply systems as standard, doubling the cutting efficiency. For the processing of brittle materials such as glass, all contact modules are made of soft-based materials to effectively avoid damage to the cutting parts. In addition, the equipment can adjust the transmission speed according to the production rhythm of the production line, with the fastest speed reaching 20 meters per minute.

Size available (X*Y) (mm)

3000*2000

APW-V6-BG3540BA-DXACWZ

It is suitable for users who need to process plates and pipes at the same time, such as machinery manufacturing, building decoration and other industries. It can effectively save equipment costs and improve equipment utilization

The plate-tube integrated series waterjet cutter integrates the plate and tube cutting functions, realizing “one machine for two purposes”, which greatly reduces equipment investment and site occupation. Its double workbench design, one table is used for plate cutting, and the other table is used for tube processing, without interfering with each other. The innovative tube chuck has sand and water-proof functions, which can achieve precise positioning and precision rotation to meet the high-precision requirements of the waterjet cutter. The support mechanism adopts segmented, sliding multi-angle support wheels, which can be flexibly adjusted in the horizontal and vertical directions to ensure the concentricity and stability when processing different pipe fittings. In addition, the ejector device at the end of the chuck further improves the processing accuracy and safety.

Size available (X*Y*φ) (mm)

2000*4000*10; 2000*5000*10; 2000*6000*10; 2000*4000*15; 2000*5000*15; 2000*6000*15

APW-A15-B-R1830

It is suitable for industries such as aerospace, automobile manufacturing, medical equipment, etc. that require extremely high processing accuracy and complexity, providing users with customized solutions.

The customized waterjet cutter series includes robot cutting machine, impeller cutting machine, etc., which are designed for specific industries and complex processing needs.

Its high flexibility and customization capabilities can meet the user’s personalized needs in special materials, complex shapes or high-precision processing

APW-V6-YL1010-DXACWZ