about water jet

Learn about APW’s water jet cutting machine technology, high-precision cutting solutions, and innovative water jet applications for metal, stone, and industrial materials.

Basic Principles

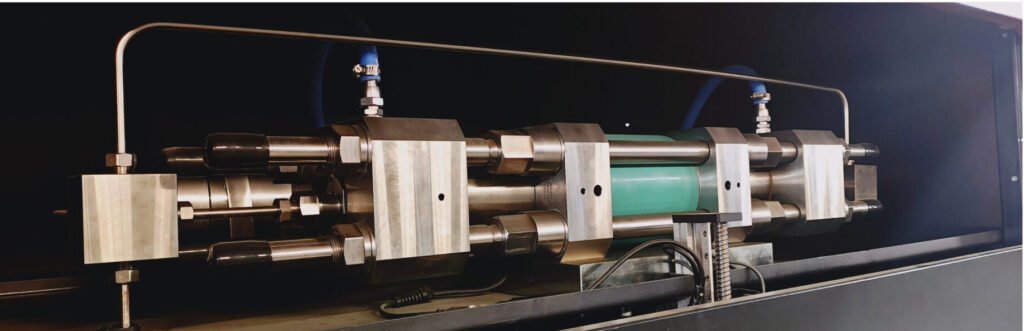

A waterjet is a high-pressure stream of water, and in some cases, an abrasive material is added. The high-pressure water is generated by a specialized pump. When pure water is used, it is suitable for cutting relatively soft materials. For harder materials, abrasive particles such as garnet are mixed with the water. The high-pressure water jet, whether pure or abrasive-laden, can cut through materials by eroding them at a molecular level.

APPLICATIONS

Industrial Cutting

- In the manufacturing industry, waterjet is used to cut various metals like stainless steel, aluminum, and copper. For example, in the automotive industry, water jet cutting can be used to shape components such as engine parts and body panels with high precision.

- In the aerospace sector, waterjet is used to cut lightweight yet strong materials like carbon fiber composites. This technology ensures minimal damage to the composite structure, maintaining its integrity and performance.

- For non-metallic materials such as plastics, rubber, and stone, waterjet cutting provides a clean and accurate cut. It is often used in the construction industry for cutting marble and granite slabs.

Surface Cleaning

- High-pressure waterjet can be used for surface cleaning tasks. In industrial settings, they are used to remove rust, paint, and other contaminants from surfaces. For example, in shipyards, waterjet is used to clean the hulls of ships, removing barnacles and old paint layers.

- In the food industry, waterjet is used for cleaning equipment and facilities, ensuring hygiene standards are met.

Mining and Quarrying

- Waterjet is used in mining operations to break down rocks and extract minerals. In some cases, they can be used as an alternative to traditional blasting methods, reducing environmental impact and noise pollution.

- In quarries, waterjet can be used to cut large blocks of stone into smaller, more manageable pieces for transportation and further processing.

Advantages

Precision

Waterjet cutting offers high precision, with the ability to create intricate shapes and patterns. The narrow kerf (the width of the cut) allows for efficient use of materials and reduces waste.

No Heat Affected Zone

Since it is a cold cutting process, there is no heat-affected zone. This is crucial for materials where heat could change their properties, such as certain metals and composites.

Versatility

It can cut a wide variety of materials, from soft polymers to hard metals and natural stones. The ability to switch between pure water and abrasive waterjet makes it suitable for different cutting requirements.

Environmentally Friendly

When compared to some traditional cutting methods, waterjet technology produces less waste and fewer harmful emissions. The use of water and, in some cases, natural abrasive materials contributes to its environmental appeal.

Considers FAQ

1. What is the cost of an APW water jet cutter?

The initial investment in an APW water jet cutter, including high-pressure pumps and cutting heads, can be significant. Additional operating costs may include abrasive materials, electricity, and routine maintenance. Despite the cost, water jet cutters provide high precision and versatility, making them a valuable long-term investment for industrial applications.

2. How often does a water jet cutter require maintenance?

Regular maintenance is essential to ensure optimal performance of a water jet cutter. Key tasks include checking for leaks, replacing worn-out parts, and maintaining the quality of water and abrasive systems. Following the manufacturer’s guidelines helps extend machine life and maintain cutting precision.

3. What safety precautions are needed when using a water jet cutter?

Due to the ultra-high pressure of water jet cutters, safety is critical. Operators should undergo proper training and always use protective equipment. Implementing strict safety protocols helps prevent accidents and ensures safe operation in industrial environments.

4. What are the advantages of using water jet technology?

Water jet cutting technology offers several advantages, including: high-precision cutting with smooth edges, versatility for materials like metal, stone, and composites, cold cutting without heat-affected zones, and environmentally friendly operations with minimal waste.

5. What industries use APW water jet cutters?

APW water jet cutters are widely used across industries such as manufacturing, aerospace, shipbuilding, automotive, and construction. Their precision, flexibility, and ability to handle diverse materials make them ideal for both industrial production and specialized engineering applications.