In the high-end residential, hotel, and custom countertop industries, Water Jet Cutting has become the mainstream technology for processing stone, tile sheets, and ceramic wash basins. Especially in the field of ceramic waterjet cutting, waterjet technology, with its cold cutting and zero heat-affected zone, is gradually replacing traditional mechanical cutting methods.

However, many customers may not realize that sheet cutting and ceramic basin cutting differ fundamentally in process logic, equipment setup, and detection methods.

Here will systematically explain:

- The technical challenges of ceramic waterjet cutting on different products

- Why sheet cutting requires a heavy-duty platform + laser detection

- Why ceramic basins require fixture + laser detector + 5-axis waterjet

- The real value of ±75° 5-axis waterjet

- Where to find actual videos and technical specifications

1. Ceramic Waterjet Advantages

- Cold cutting, no thermal stress

- Smooth edges, low chipping

- No stress concentration

- Free-form curves, bevels, and 3D shapes

- Suitable for glazed and dense ceramics

2. Stone / Tile Sheet Cutting: Platform & Laser Detector

Challenges:

- Large size & heavy weight

- Warpage & uneven thickness

Recommended:

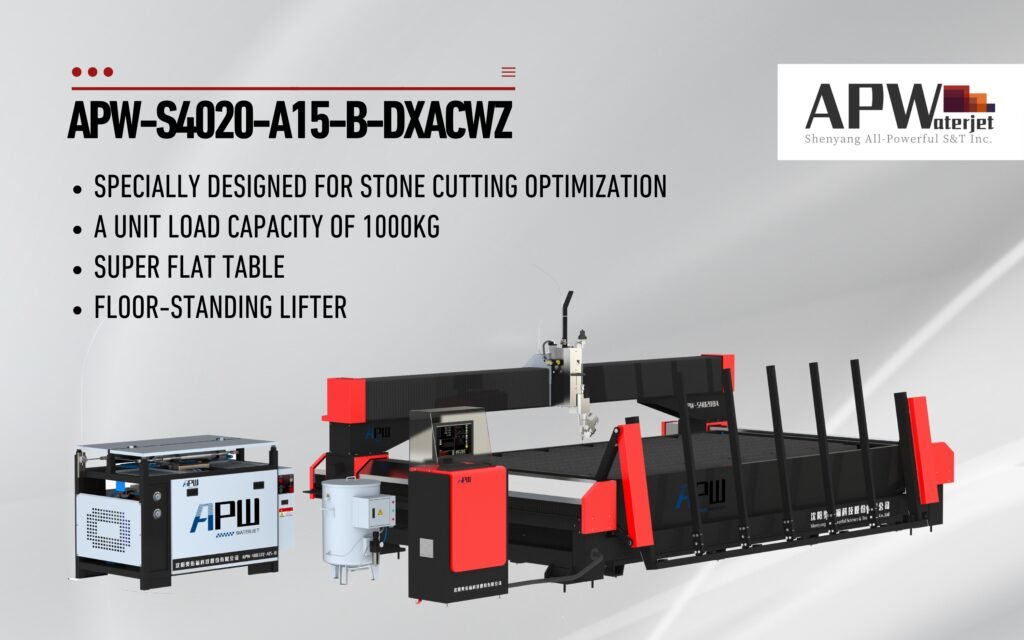

S4020 Heavy-duty platform + 5-axis waterjet + Laser detection

Laser detector:

- Scans sheet before cutting

- Detects height variations

- Adjusts Z-axis & compensates path

Effect: reduces damage, ensures cut-through, improves yield

3. Ceramic Wash Basin Cutting

Challenges:

- Slight dimensional differences

- Non-symmetrical edges

- Local thickness variation

- Batch deviations

Manual positioning:

- Highly dependent on skill

- Bevel angles inconsistent

- Installation fit unpredictable

4. Best Process Combination

Fixture + Laser Detector + 5-Axis Waterjet

Steps:

- Fixture: establishes geometry baseline

- Laser Detector: scans real edges, heights, angles → corrects program

- 5-Axis Waterjet: ensures ±75° tilt, covers most bevels & sloping surfaces

5. Why AC5 Axis is Recommended

| Feature | AB5 Axis | AC5 Axis |

| Tilt range | ±12° | ±75° |

| Complex bevels | no | yes |

| Ceramic basin | no | yes |

| Stone/tile | yes | yes |

| Flexibility | Low | High |

| Long-term use | Limited | No issue |

AC5 = one-time setup, avoids upgrade cost and rework.

6. Waterjet + Laser Detector = Solve Ceramic Consistency Issues

- Waterjet: solves miscut

- Laser detector: solves misalignment

- 5-axis waterjet: solves angle inconsistency

Effect: perfect fit, consistent bevels, reduced labor, high-quality finish

7. Video Demos

- S4020 Stone / Tile Sheet: https://www.youtube.com/watch?v=qQh31ZHcyt4&t=2s

- Ceramic Basin 5-Axis Cutting: https://www.youtube.com/watch?v=sM8uQCF2FUY

8. S4020 Equipment & Tech Table

- Product page: https://apwwaterjet.com/stone-cutting-water-jet-cutter-apw-s4020-dxacwz/

- PDF Tech Table: https://apwwaterjet.com/wp-content/uploads/2025/07/APW-S4020-A15-B-DXACWZ.pdf

9. Learn More

Stone Cutting, Buying Guides, How-to & Technical Guides:

https://apwwaterjet.com/articles-on-water-jet-cutting/

10. Contact Sales

- Material + process + budget → best solution

- Compare 3-axis vs 5-axis / laser detection → one-time correct selection

After reading this article, you now understand the different process requirements for ceramic waterjet cutting on stone/tile sheets and ceramic wash basins, as well as the recommended equipment combination: S4020 heavy-duty platform + AC5 axis + laser detector. This setup not only ensures sheet flatness but also compensates for slight dimensional variations in ceramic basins and maintains consistent bevel angles, reducing labor dependency and rework. For high-end residential, hotel, or custom countertop projects, waterjet cutting offers an efficient, precise, and controllable solution. To explore technical specifications, operating tips, or customized setups, it is recommended to contact APW sales engineers for expert guidance and tailored process advice.

FAQ

Q1: What is ceramic waterjet cutting?

A1: Ceramic waterjet cutting uses high-pressure water, often with added abrasive, to cut stone, ceramic sheets, or ceramic wash basins. Its advantages include cold cutting, zero heat-affected zone, smooth edges, low chipping, and the ability to cut curves and complex shapes.

Q2: How does sheet cutting differ from ceramic basin cutting?

A2: Sheet cutting focuses on platform stability and height compensation, typically using a heavy-duty platform + laser detector. Ceramic basin cutting requires a fixture + laser detector + 5-axis waterjet to ensure consistent bevel angles and compensate for slight dimensional variations.

Q3: Why is AC5 5-axis waterjet recommended?

A3: The AC5 axis provides ±75° tilt, covering almost all bevels and sloped surfaces. It is suitable for both basins and sheets, ensuring angle consistency and flexible cutting while avoiding future upgrade costs.

Q4: What role does the laser detector play in cutting?

A4: The laser detector scans the actual height and edge deviations of sheets or basins and automatically adjusts the cutting path, reducing damage and ensuring precise cuts and consistent bevel angles.

Q5: What applications is the S4020 heavy-duty platform suitable for?

A5: The S4020 platform is designed for large stone and ceramic sheets, with high rigidity and load capacity. It supports 5-axis waterjet and laser detection, enabling high-efficiency, high-precision cutting for professional fabrication.