Waterjet cutting has become a preferred method in modern manufacturing and processing industries due to its high precision, low thermal impact, and versatility in cutting metals, stones, and glass. Depending on the cutting method, waterjet cutting is mainly divided into Abrasive Water Jet (AWJ) and Pure Water Jet (PWJ).

1. Overview of Waterjet Cutting

Waterjet cutting uses a high-speed water stream to cut materials. High-pressure pumps increase water pressure to 3000–6000 bar, and the water exits the nozzle at speeds of hundreds of meters per second to impact the material surface. Compared to traditional mechanical or laser cutting, waterjet cutting has several advantages:

- Cold cutting process: Minimizes thermal deformation or hardening.

- High precision: Capable of cutting complex contours and varying thicknesses.

- Eco-friendly and safe: No chemical etchants; easy waste handling.

2. Abrasive Water Jet (AWJ) vs Pure Water Jet (PWJ)

Abrasive Water Jet (AWJ)

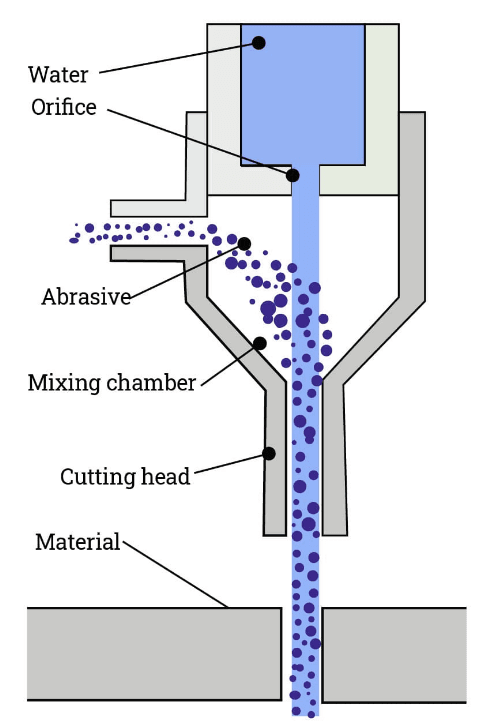

AWJ mixes fine abrasive particles (like garnet) into the high-speed water flow to enhance cutting capacity, suitable for hard or thick materials.

Features:

- Cuts steel, titanium alloys, composites, and other hard materials.

- Efficient for thick materials and industrial processing.

- Supports 2D and 3D contour cutting.

Applications:

- Aerospace: Precise cutting of titanium alloy parts

- Automotive: Composite material sheet cutting

- Stone processing: Thick marble and granite cutting

Operation and Management:

Effective abrasive supply management, nozzle maintenance, and water circulation are key to ensuring cutting quality and cost control. (Reading <best practices for managing water jet abrasive>)

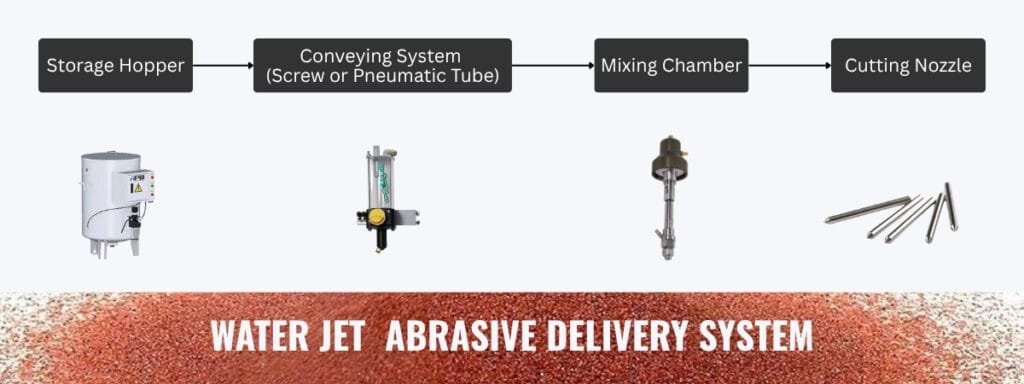

Abrasive Delivery System and Wear Parts

The abrasive moves from the storage hopper to the waterjet cutting head through the following steps:

- Storage Hopper: Holds dry abrasive particles.

- Conveying System (Screw or Pneumatic Tube): Transfers abrasive to the mixing chamber.

- Mixing Chamber: Combines abrasive with high-pressure water to form the abrasive waterjet.

- Cutting Nozzle: High-speed abrasive water stream cuts the material.

Wear Parts:(Reading<parts list>)

https://www.iqsdirectory.com/articles/water-jet-cutting.html

- Nozzle: Directly impacted by high-speed abrasive, needs regular replacement.

- Mixing Tube: Subjected to abrasion from the abrasive water flow.

- Screw Conveyor Liner: Wears due to abrasive friction.

Waste Abrasive Management and Environmental Compliance

During cutting, a large amount of abrasive settles in the water tank. Proper handling includes:

- Sediment separation: Use grit chambers or filters to separate abrasive from water.

- Drying and recycling: Dehydrate for partial reuse.

- Waste disposal: Non-reusable abrasive must be disposed of according to local environmental regulations.

- Water circulation: Filtered and recirculated to minimize water consumption.

Pure Water Jet (PWJ)

PWJ does not use abrasives and is suitable for thin, flexible, or highly delicate materials.

Features:

- Avoids surface scratches or material damage

- Fine cutting of glass, plastics, rubber, etc.

- Achieves micron-level precision

Applications:

- Electronics: Flexible PCB cutting

- Food processing: Cold cutting

- Medical devices: Plastic or thin metal component cutting

3. Choosing AWJ or PWJ

| Requirement | Recommended Technology | Reason |

| Hard thick plates | AWJ | Abrasive enhances cutting ability, high efficiency |

| Thin/flexible materials | PWJ | Protects surface, high precision |

| Complex contours | AWJ | Supports 5-axis cutting, 3D shaping |

| High surface finish | PWJ | No abrasive, no micro-scratches |

4. Waterjet Cutting Equipment and Advanced Technology

Modern waterjet machines feature multi-axis cutting heads (e.g., 5-axis), automatic feeding, and energy-efficient pumps. Examples:

- APW Series: Models for stone, metal, and glass

- Automated transfer lines: Increase continuous production efficiency

- Energy-saving pump design: Reduce electricity consumption, extend equipment life

5. Conclusion

Waterjet cutting can flexibly use AWJ or PWJ depending on material and application. AWJ suits thick, hard materials and complex contours, while PWJ is ideal for precision thin materials. Proper maintenance of wear parts and compliant handling of waste abrasives ensures safe, efficient, and sustainable production.

6. FAQ (TALK WITH SALES)

Q1: Which is better for cutting thick steel plates?

A: AWJ is better for hard and thick materials; PWJ is suited for thin or flexible materials.

Q2: How is abrasive delivered to the cutting head?

A: From the storage hopper via screw or pneumatic tube into the mixing chamber, then combined with high-pressure water to form the abrasive waterjet.

Q3: How to clean waste abrasive from the water tank?

A: Separate sediment using grit chambers or filters, recycle usable abrasive, and dispose of non-reusable abrasive per environmental regulations.

Q4: What is the typical nozzle life?

A: Depends on abrasive hardness, particle size, pressure, and cutting time; generally 20–100 hours.

Q5: Does waterjet cutting generate a heat-affected zone?

A: No, it is a cold cutting process.

Q6: Can waterjets cut complex 3D contours?

A: Yes, multi-axis AWJ machines can achieve 3D contour cutting.

Q7: Is AWJ environmentally friendly?

A: When waste abrasives are properly handled and water is recycled, it is sustainable.

Q8: What is the typical water-to-abrasive ratio?

A: Usually 15–30% abrasive by volume, adjusted according to material and thickness.