A water jet cutting machine is one of the most versatile tools in modern manufacturing. It is widely used in industries ranging from aerospace and automotive to stone fabrication and glass processing. Unlike traditional cutting methods that rely on heat or mechanical blades, a water jet cutting machine uses high-pressure water—sometimes mixed with abrasive particles—to cut through a wide range of materials with extreme precision.

But how does each part of a water jet cutting machine contribute to the process? To understand this, we can divide the workflow into three main stages: pre-cutting, cutting, and after-cutting. Each stage involves specific components working together to ensure efficiency, accuracy, and quality of the final product.

Pre-Cutting Stage: Preparation and Setup

Before the actual cutting begins, the machine and material must be prepared. The pre-cutting stage is critical because even the smallest mistake in setup can lead to wasted material, downtime, or poor cutting quality.

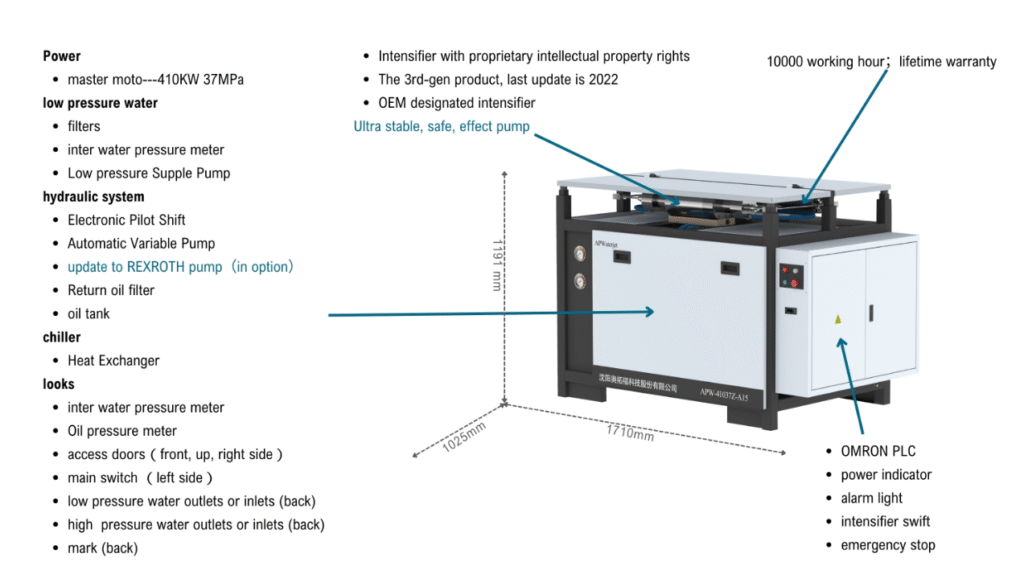

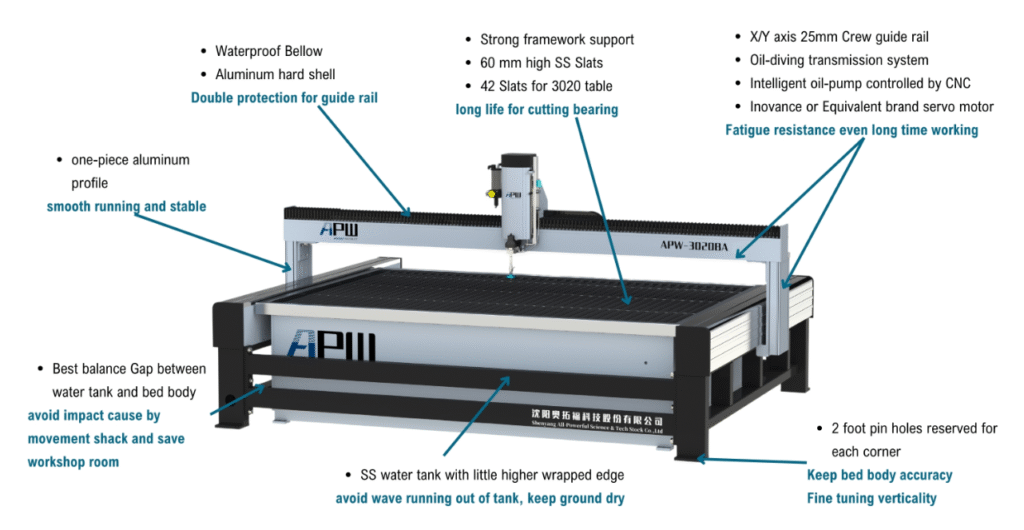

1. High-Pressure Pump

The pump is the heart of the water jet cutting machine. During pre-cutting, it pressurizes water up to 60,000–90,000 psi (depending on the system). The stable and consistent pressure it generates is essential for cutting performance later.

2. Water Treatment System

Since impurities in water can damage the pump or clog the nozzle, a filtration system ensures the water is clean and suitable for ultra-high pressure. Pre-cutting preparation involves monitoring filters and making sure the supply is reliable.

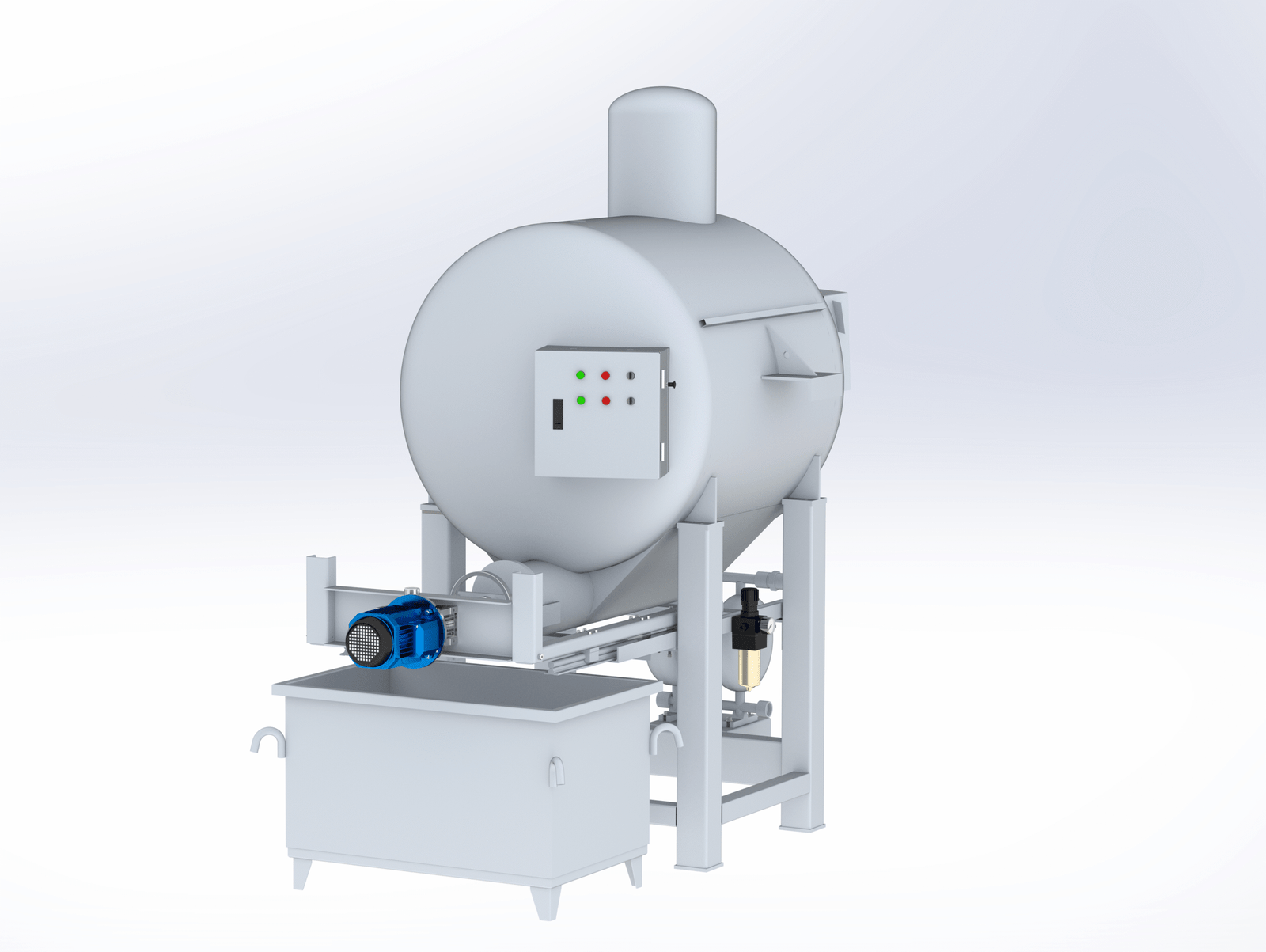

3. Abrasive Delivery System

For cutting harder materials such as metal, stone, or ceramics, abrasive particles (usually garnet) are mixed with water. In the pre-cutting stage, operators check the abrasive hopper, flow control, and feeding lines to ensure consistent delivery during operation.

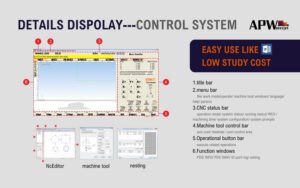

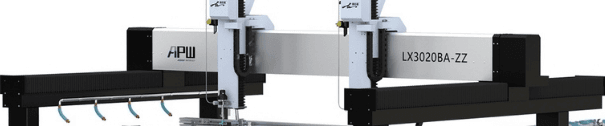

4. Control Software and Motion System

Before cutting, the operator programs the desired cutting path using CAD/CAM software. The motion system, which includes servo motors, ball screws, and linear guides, receives instructions on how to move the cutting head over the workpiece. Calibration, alignment, and dry runs are often part of pre-cutting preparation.

5. Cutting Table and Fixtures

The workpiece is secured on the cutting table, often submerged in water to reduce noise and splash. Proper fixturing ensures the material remains stable during cutting, preventing vibration or shifting.

The pre-cutting stage is all about ensuring that pressure, water quality, abrasives, software, and material positioning are ready. Without these checks, the cutting stage cannot achieve high precision.

Cutting Stage: Core Operation of the Water Jet Cutting Machine

The cutting stage is where the action happens. Here, several machine components work in harmony to deliver smooth, accurate cuts.

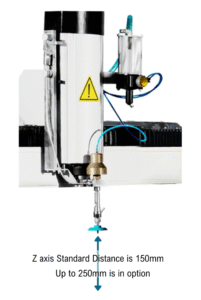

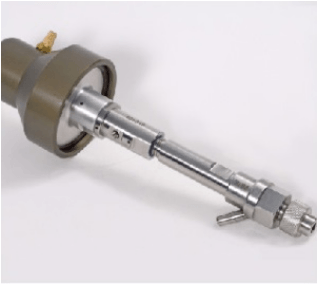

1. Orifice (Jewel)

At the cutting head, water passes through a tiny orifice made of diamond, sapphire, or ruby. This converts ultra-high-pressure water into a thin, high-velocity jet—sometimes faster than the speed of sound. The orifice’s precision determines the sharpness and consistency of the jet stream.

2. Mixing Chamber

If the job requires abrasive cutting, the mixing chamber comes into play. Here, abrasive particles mix with the water jet, creating a powerful stream capable of eroding even the hardest materials. This is where water-only cutting transitions into abrasive water jet cutting.

3. Nozzle (Focusing Tube)

The mixed stream exits through the nozzle or focusing tube. This part focuses the water-abrasive mixture into a narrow, high-energy beam that cuts into the material. The nozzle’s wear resistance is critical, as abrasive particles can erode the inner wall over time.

4. Cutting Head Movement System

The cutting head is mounted on a CNC-controlled gantry or arm, which moves it along X, Y, and sometimes Z axes. This system ensures the cutting head follows the programmed path precisely, allowing for complex shapes and intricate designs.

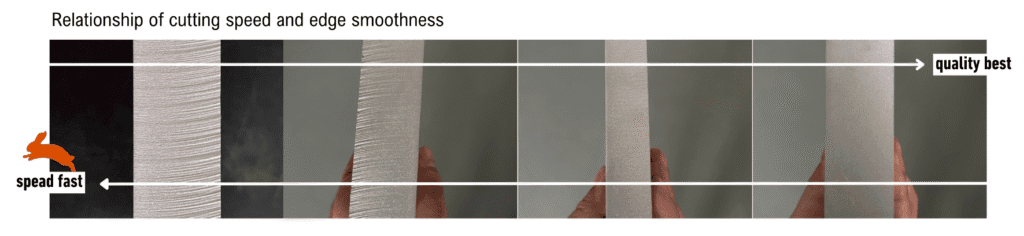

5. Water and Abrasive Flow Control

During cutting, valves regulate the exact amount of water and abrasive delivered to the head. Too much or too little abrasive can affect cutting efficiency and edge qu

ality. Flow meters and regulators keep the process consistent.

6. Cutting Table and Water Bed

As the jet pierces through the material, the table below absorbs the remaining energy. Many cutting tables use a water bed to dissipate the jet stream, reduce noise, and minimize dust. Some are equipped with slats that can be replaced easily when worn out.

The cutting stage is powered by the orifice, mixing chamber, nozzle, and motion system, all working together to convert pressurized water into a precision cutting tool.

After-Cutting Stage: Finishing and Cleanup

Once the cutting is complete, the process is not over. The after-cutting stage ensures the part is finished properly, waste is handled, and the machine is maintained for future operations.

1. Sludge Removal System

As water jet cutting uses abrasives, a significant amount of sludge accumulates at the bottom of the cutting tank. Specialized removal systems pump out this sludge, preventing buildup that could hinder performance.

2. Part Inspection

After cutting, operators inspect the part for dimensional accuracy, edge quality, and taper. Since water jet cutting produces no heat-affected zone (HAZ), the edges are usuall

y clean, but some applications require light sanding or polishing.

3. Abrasive Recycling

Some facilities use abrasive recycling systems to clean and reuse spent garnet. This reduces operating costs and environmental impact. After cutting, operators may transfer abrasive waste for processing.

4. Pump and Nozzle Maintenance

After cutting, the machine is checked for wear. Seals, orifices, and nozzles may require replacement after a certain number of hours. Proper maintenance extends machine life and ensures consistent results in the next job.

5. Software Report and Data Logging

Modern water jet cutting machines often generate reports after each job, including material usage, time spent, and abrasive consumption. These logs help in production planning and cost analysis.

The after-cutting stage focuses on cleaning, inspection, recycling, and maintenance, ensuring that the water jet cutting machine remains efficient and ready for the next project.

Why Understanding the Parts and Stages Matters

A water jet cutting machine is more than just high-pressure water—it is a precisely engineered system where every part has a role. Understanding what each component does during pre-cutting, cutting, and after-cutting helps operators:

- Reduce errors during setup

- Optimize cutting speed and quality

- Extend machine lifespan through proper maintenance

- Lower costs by managing abrasives and consumables efficiently

Whether you are cutting aerospace titanium, automotive glass, or decorative stone, the principles remain the same. Each stage and part contributes to the overall success of the cutting process.

The efficiency of a water jet cutting machine lies in the synergy of its components. From the pump and control system in the pre-cutting stage, to the orifice, mixing chamber, and nozzle in the cutting stage, and finally to the sludge removal and maintenance in the after-cutting stage, every part plays a vital role.

For manufacturers, understanding these details is not only useful for operators but also crucial for decision-makers choosing the right cutting system. By recognizing how each part contributes, you can maximize performance, reduce downtime, and achieve consistent high-quality results.

In short, the success of a water jet cutting machine is a team effort—between pressure, precision, and preparation.

FAQ: Water Jet Cutting Machine

1. What materials can a water jet cutting machine cut?

A water jet cutting machine can cut a wide range of materials, including metals (steel, aluminum, titanium), stone, ceramics, glass, composites, plastics, rubber, and even food products. Its versatility comes from the option to use pure water for soft materials or add abrasives for hard materials.

2. How accurate is a water jet cutting machine?

A modern CNC water jet cutting machine can achieve accuracy within ±0.1 mm. This makes it suitable for industries such as aerospace, automotive, and medical device manufacturing where precision is critical.

3. Does a water jet cutting machine create a heat-affected zone?

No. Unlike laser or plasma cutting, a water jet cutting machine uses cold cutting technology. This means there is no heat-affected zone (HAZ), preventing material warping, hardening, or structural damage.

4. What is the difference between pure water and abrasive water jet cutting machines?

- Pure water jet cutting machines use only high-pressure water to cut soft materials like foam, rubber, textiles, and food.

- Abrasive water jet cutting machines mix garnet particles with water to cut hard materials such as metals, stone, ceramics, and composites.

5. How much maintenance does a water jet cutting machine require?

Routine maintenance includes replacing seals, checking the orifice and nozzle for wear, cleaning the abrasive lines, and removing sludge from the tank. Proper maintenance ensures consistent cutting performance and extends the lifespan of the water jet cutting machine.

ASK SALES OR VISIT APW ALIBABA SHOP TO GET A QUOTE