In the process of the rapid development of the global glass processing industry, water jet cutting machines, with their excellent performance and unique advantages, have become the core technology driving industry innovation, profoundly influencing all aspects and application fields of glass processing.

I. Global Pattern: China at the Helm, Rise of the Asia-Pacific

In the global glass processing market, China occupies a dominant position. As of 2023, China accounted for approximately 28.2% of global exports of glass and glass products. Its huge manufacturing base and strong domestic demand provide a strong impetus for industrial development. The Asia-Pacific region is an even more core growth pole. In 2021, its revenue contribution to the global glass market exceeded 40% and has maintained a rapid growth trend. This booming industry background provides broad space for the widespread application and innovative development of water jet cutting machine.

II. Application Fields: Technical Empowerment in Multiple Scenarios

III. Technical Advantages: Incomparable Processing Characteristics

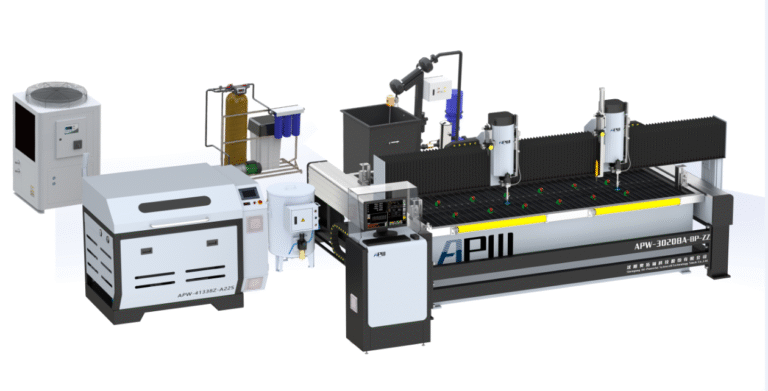

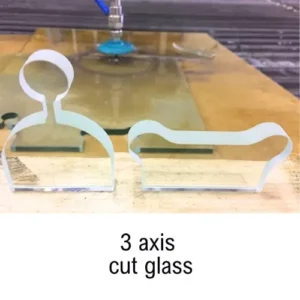

Compared with traditional equipment such as glass scribing machines, water jet cutting machine have significant advantages. The cutting accuracy of glass scribing machines is only about ±0.5mm, which is difficult to meet high-precision requirements. They also have limited processing capabilities for thick glass and heat-sensitive glass, and the edge quality after cutting is poor. However, the cutting accuracy of water jet cutter can reach within ±0.1mm, and they can easily handle glass of various thicknesses and materials. There is no vibration during the cutting process, and the edges after cutting are smooth, requiring little secondary processing. Moreover, no heat-affected zone is generated, which can perfectly preserve the original strength, light transmittance, and other properties of the glass. It is an ideal processing method that combines high efficiency and environmental protection.

IV. Industry Practices: Assistance in Promoting Industrial Upgrades